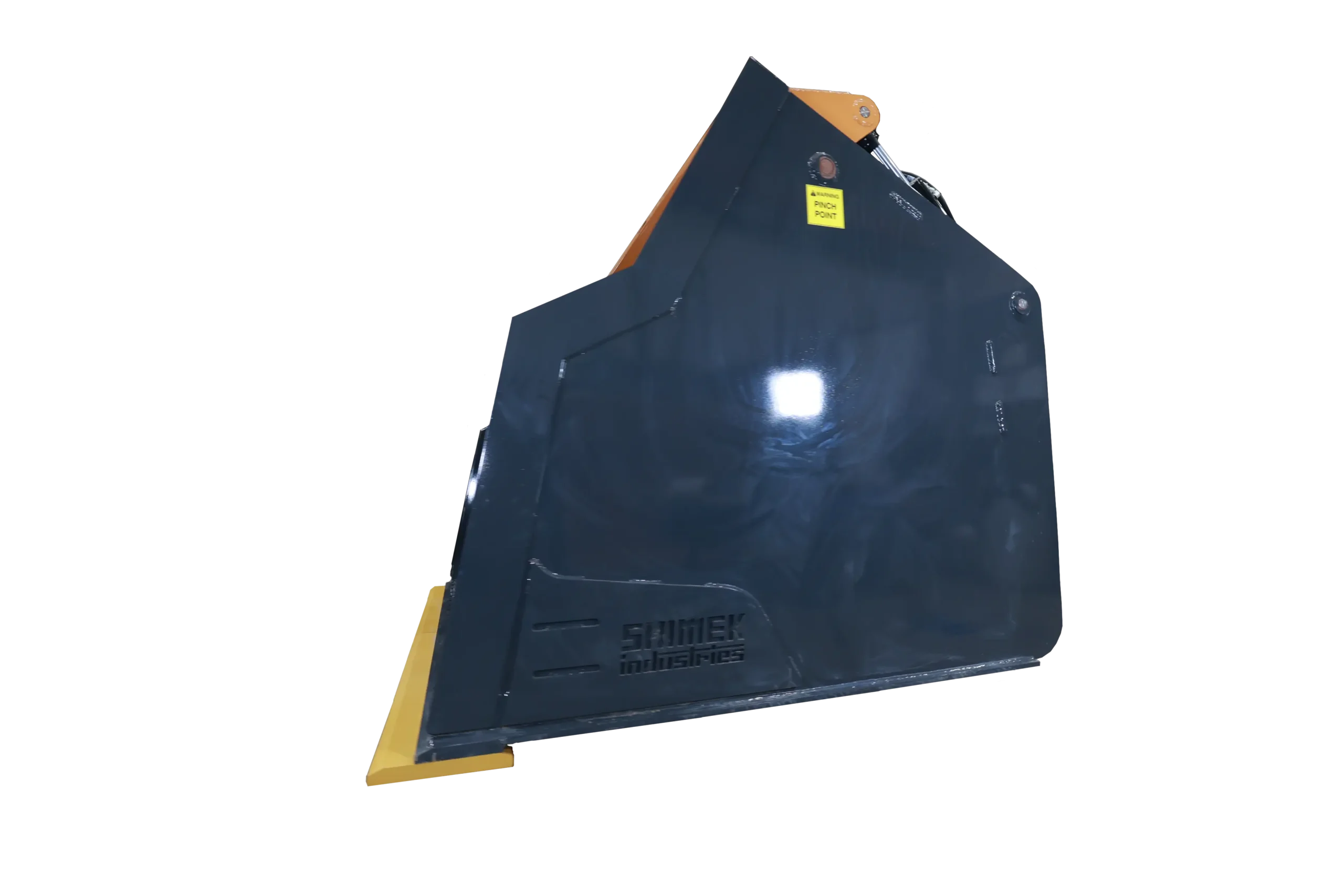

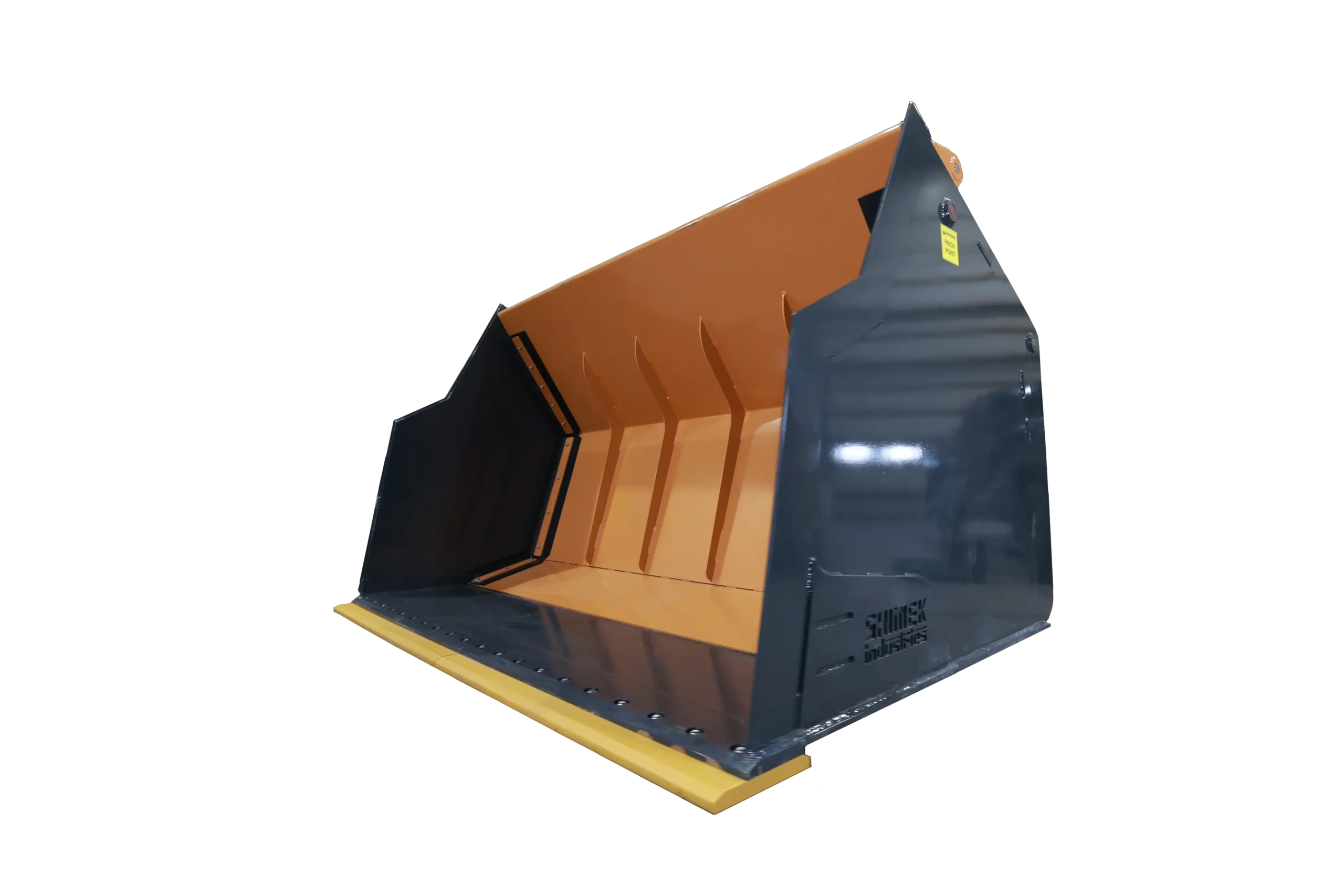

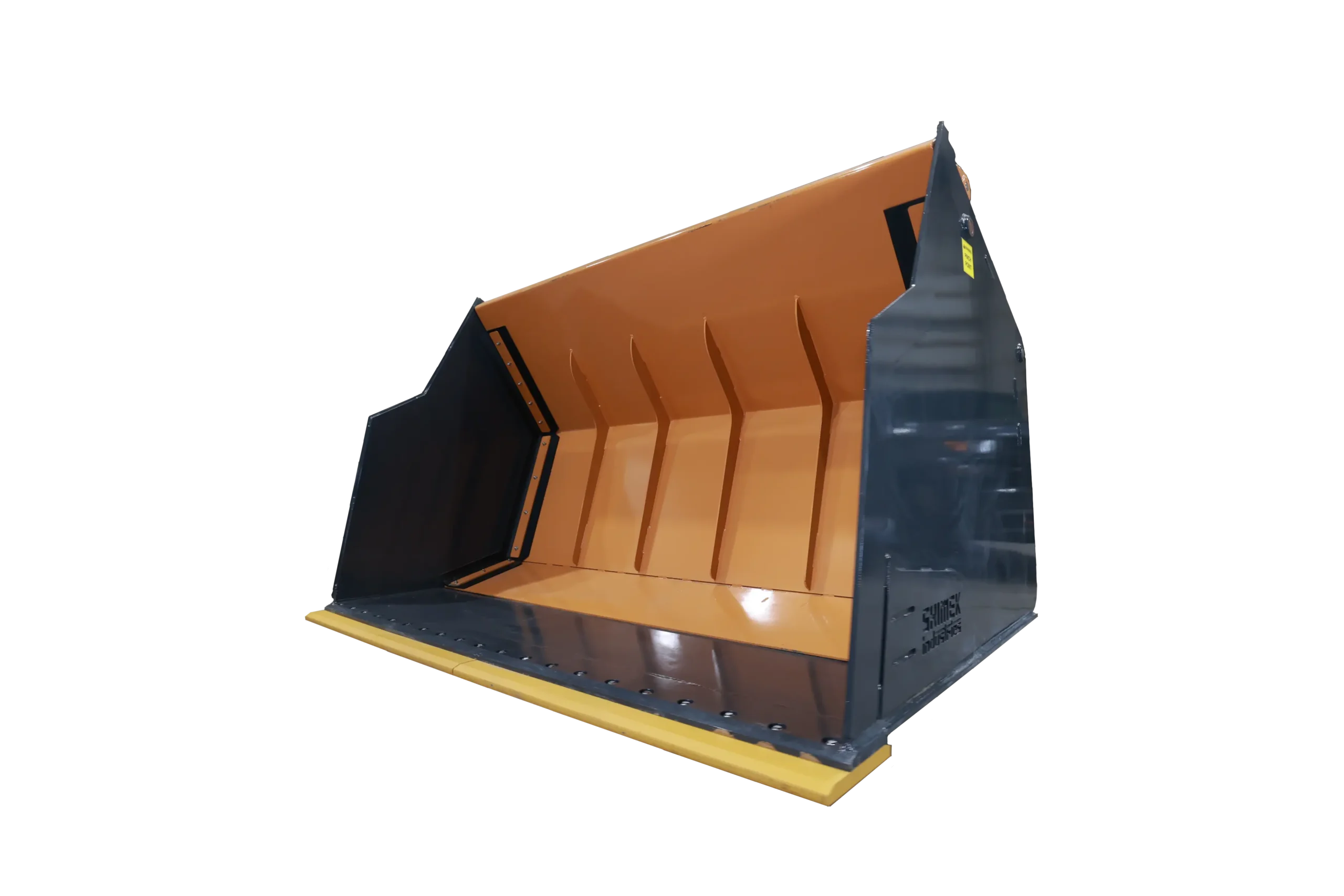

In the world of heavy machinery, your excavator or loader is the prime mover, but ensuring Shimek Ejector Bucket compatibility is the business end.

Introduction

Walk onto almost any major job site across the globe—whether it’s construction, mining, or aggregate—and you will see the undisputed leaders in yellow and orange iron: Caterpillar, John Deere, and Komatsu. These machines have earned their reputations for reliability, power, and technological advancement. They are the backbone of the industry.

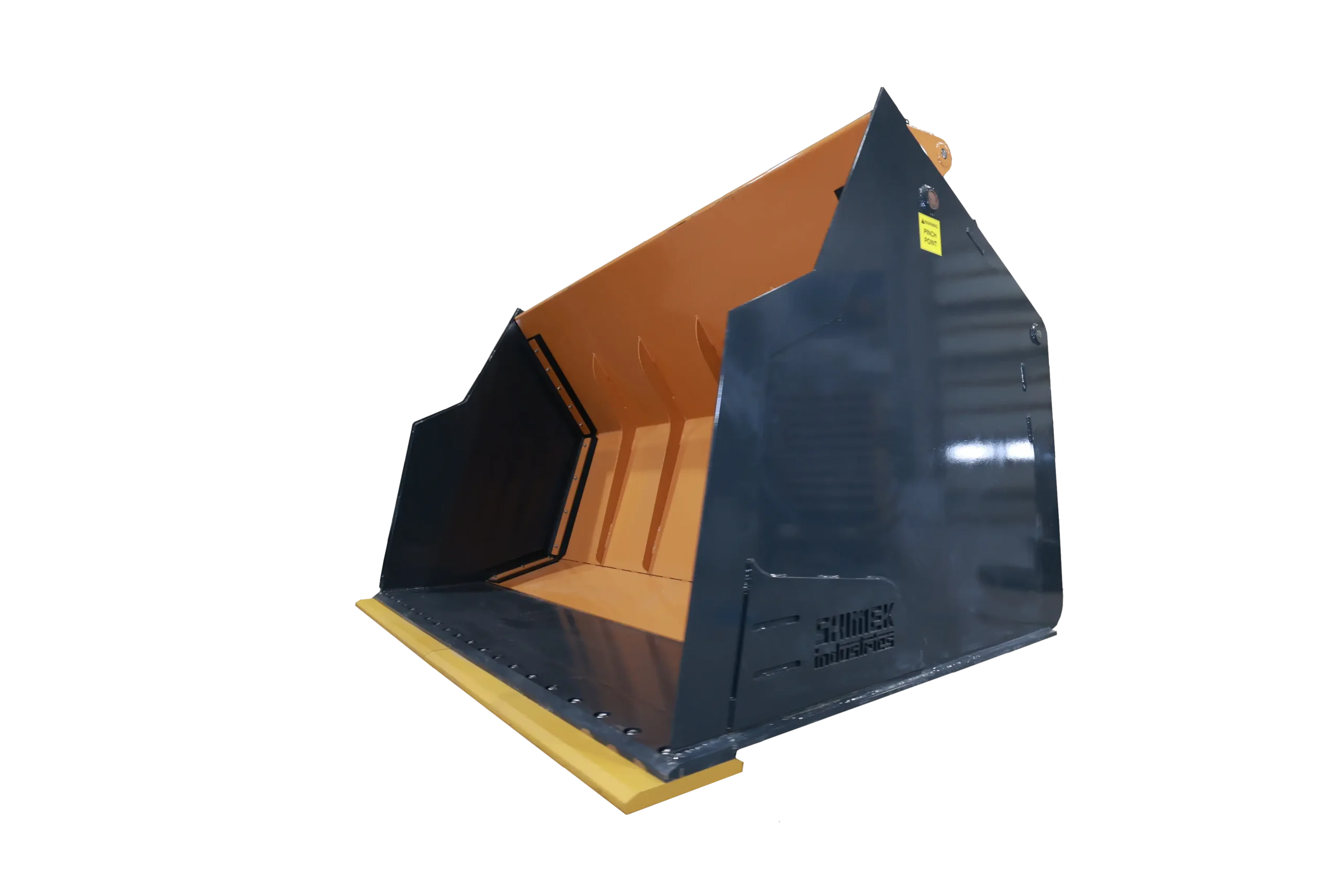

However, even a top-tier Komatsu or a brand-new Cat loader can be bottlenecked by the material it’s handling. Sticky clay, wet fly ash, or cohesive soils often refuse to dump cleanly from standard digging buckets. This leads to “carry-back,” wasted fuel, time spent banging the bucket to loosen material, and increased wear on the machine’s boom and pins.

At Shimek Industries, we believe the best machines deserve the best tools.

Pairing These Industry Powerhouses with a Shimek Ejector Bucket Can Increase Your Productivity and Decrease Maintenance

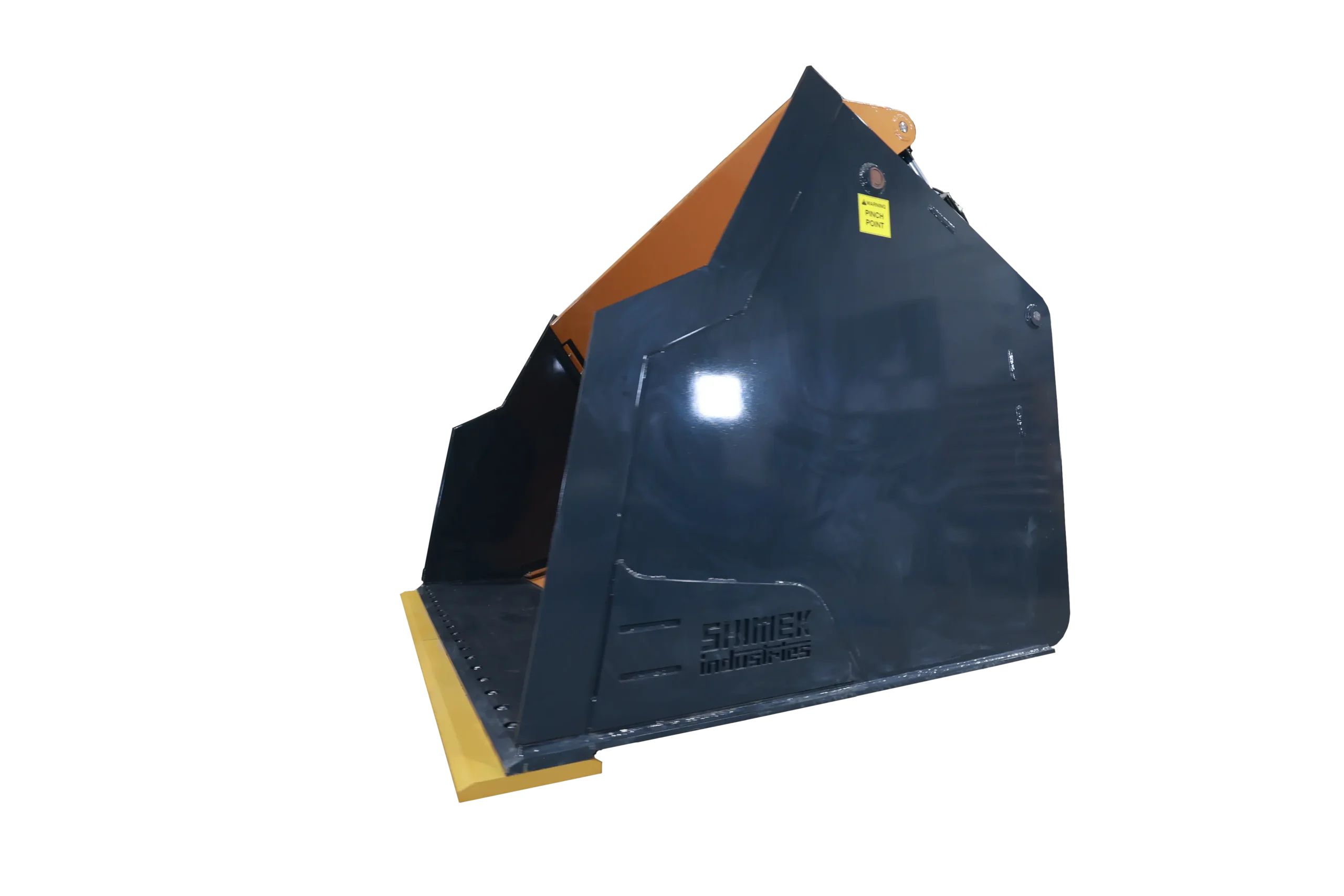

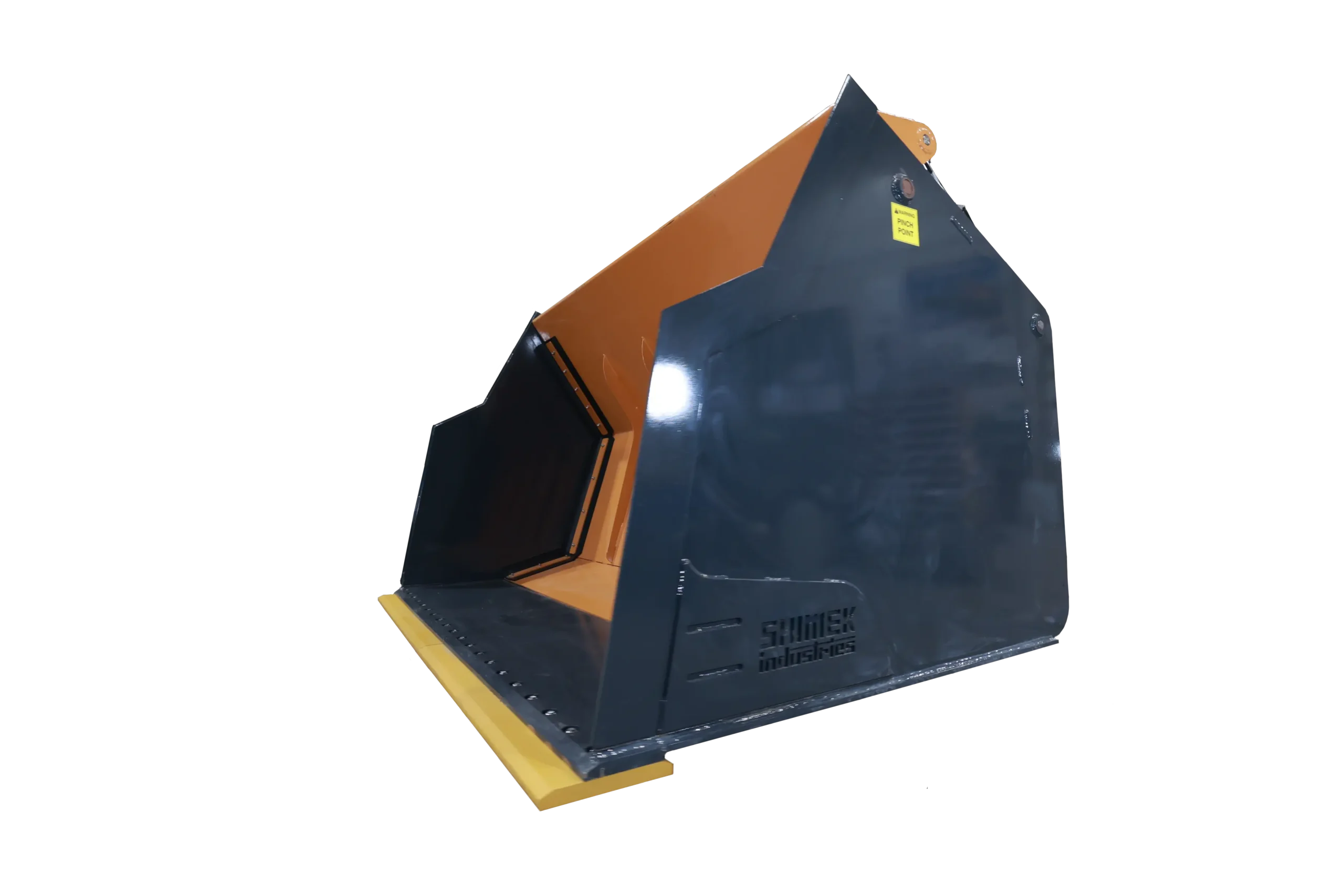

When you equip a premier prime mover with a Shimek Ejector Bucket, you change the fundamental dynamics of how you move material. Instead of relying on gravity to dump a load, our hydraulically actuated ejector plate actively pushes 100% of the material out of the bucket in seconds.

This immediate, clean dump cycle means faster cycle times and less fuel burned per ton moved. Crucially, it eliminates the need to aggressively shake the machine to dislodge stubborn material. This reduction in violent shaking translates directly to decreased maintenance costs on the carrier machine’s hydraulic cylinders, boom pins, and bushings.

But a high-performance bucket is useless if it doesn’t integrate seamlessly with the machine pushing it. The critical link between Shimek innovation and Cat, Deere, or Komatsu power is the coupler interface.

The Critical Handshake: Shimek Ejector Bucket Compatibility and Integration

The connection point between loader arms and the attachment is one of the highest-stress areas on the entire machine. If the fitment is poor, you get “slop” in the movement, reduced breakout force, and dangerous wear on the machine’s mounting points.

At Shimek Industries, we cater to all major coupler interfaces such as ISO, CAT Fusion, JRB 416, and WL KAT. We engineer our Ejector Buckets with precision-manufactured standard coupler interfaces designed specifically to match the geometry and hydraulic requirements leading the industry.

Here is how Shimek ensures a perfect handshake with the big three:

The Caterpillar Connection

Caterpillar machines are legendary for their robust build and high hydraulic pressures. If you are utilizing Cat’s proprietary quick coupler system CAT Fusion™ or dedicated pin grabbers on larger wheel loaders, Shimek has the interface capability.

Our lugging is engineered using high-tensile steel, reinforced to match Cat’s rigorous specs. For hydraulic couplers, we ensure that the Shimek interface engages smoothly with the locking mechanisms, providing a zero-slack fit that transfers 100% of the Cat machine’s breakout force to the digging edge.

The John Deere Integration

John Deere focuses heavily on efficiency and operator ease. Their coupler systems are typically a mix between ISO or JRB depending on the region.

We ensure that the hydraulic lines required to operate the ejector circuit are routed cleanly, matching Deere’s auxiliary port layouts to prevent hose pinching or rubbing during full-range articulation. The fit is “hand-in-glove,” ensuring the bucket feels like a natural extension of the Deere arm.

The Komatsu Interface

Komatsu machines are increasingly recognized for their intelligent machine control and precise hydraulic management. When fitting a hydraulic attachment like an ejector bucket, ensuring the attachment doesn’t confuse the machine’s sensing systems is vital.

Shimek engineers the hydraulic circuit of our ejector buckets to operate efficiently within the auxiliary flow and pressure parameters of Komatsu carriers. Mechanically, our coupler fittings can match most Komatsu machines, ensuring that accuracy isn’t lost due to a sloppy mechanical connection at the bucket pins.

The Shimek Standard

We know that your Cat, Deere, and Komatsu machines represent significant capital investments. You shouldn’t compromise their performance with sub-par attachments.

Shimek Industries builds our coupler interfaces with the same heavy-duty philosophy as the rest of our buckets. We do not machine our coupler hooks; they are plasma cut to ensure durability and precision.

When you choose a Shimek Ejector Bucket, you aren’t just solving a material handling problem; you are ensuring a seamless, powerful integration with the industry’s best machinery.

Ready to stop banging your buckets and start moving more payload? Contact Shimek Industries today to discuss the perfect ejector bucket fitment for your fleet.