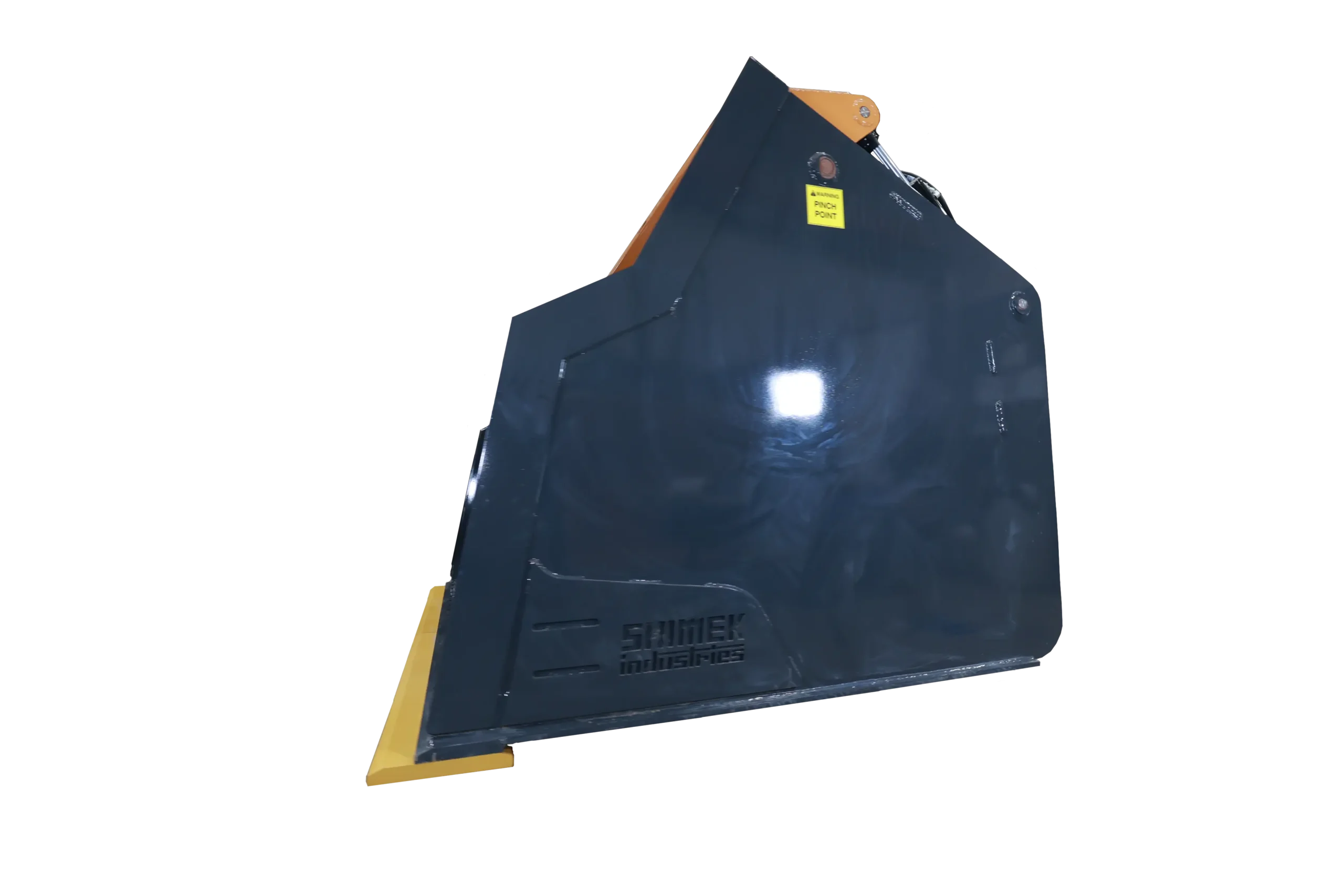

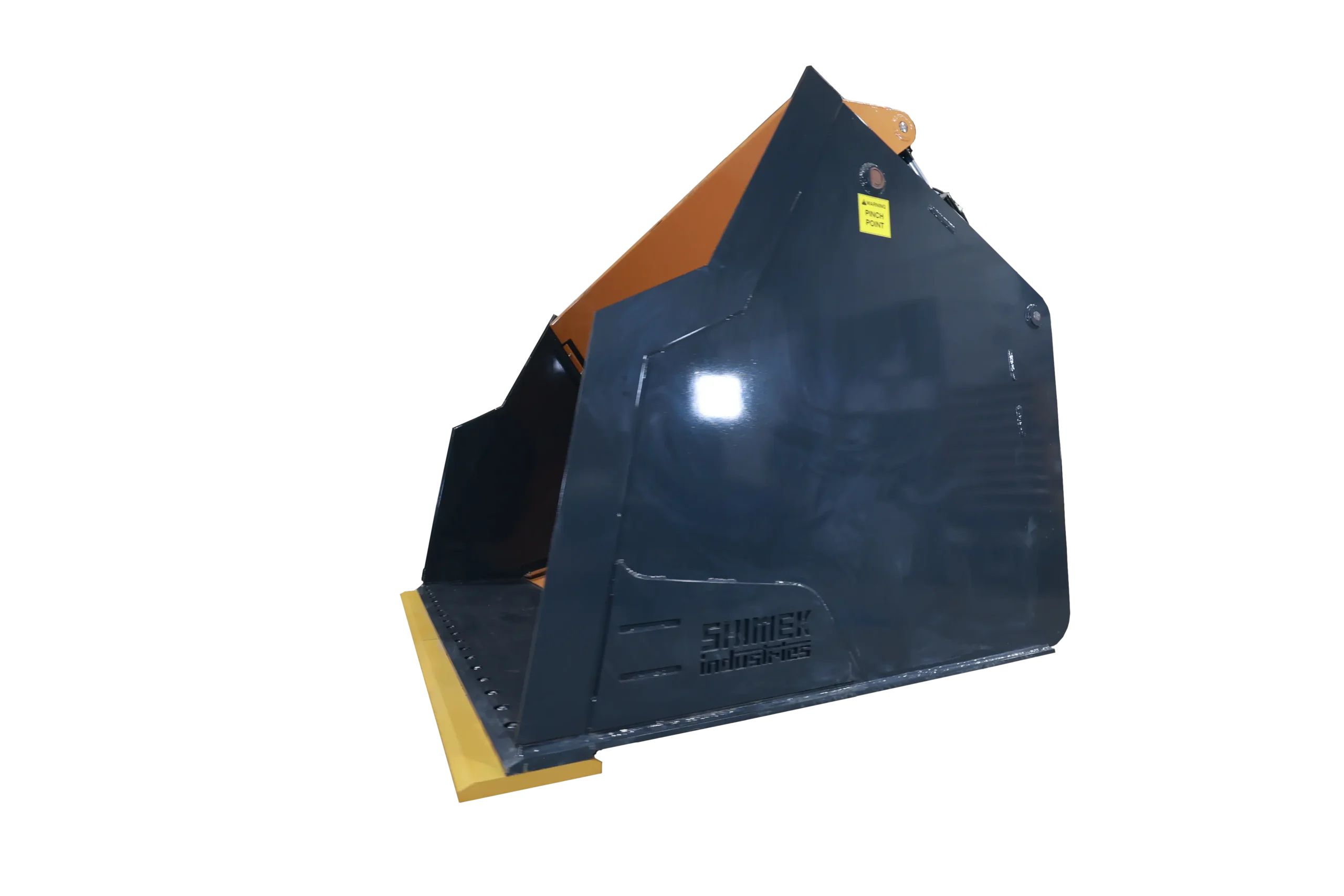

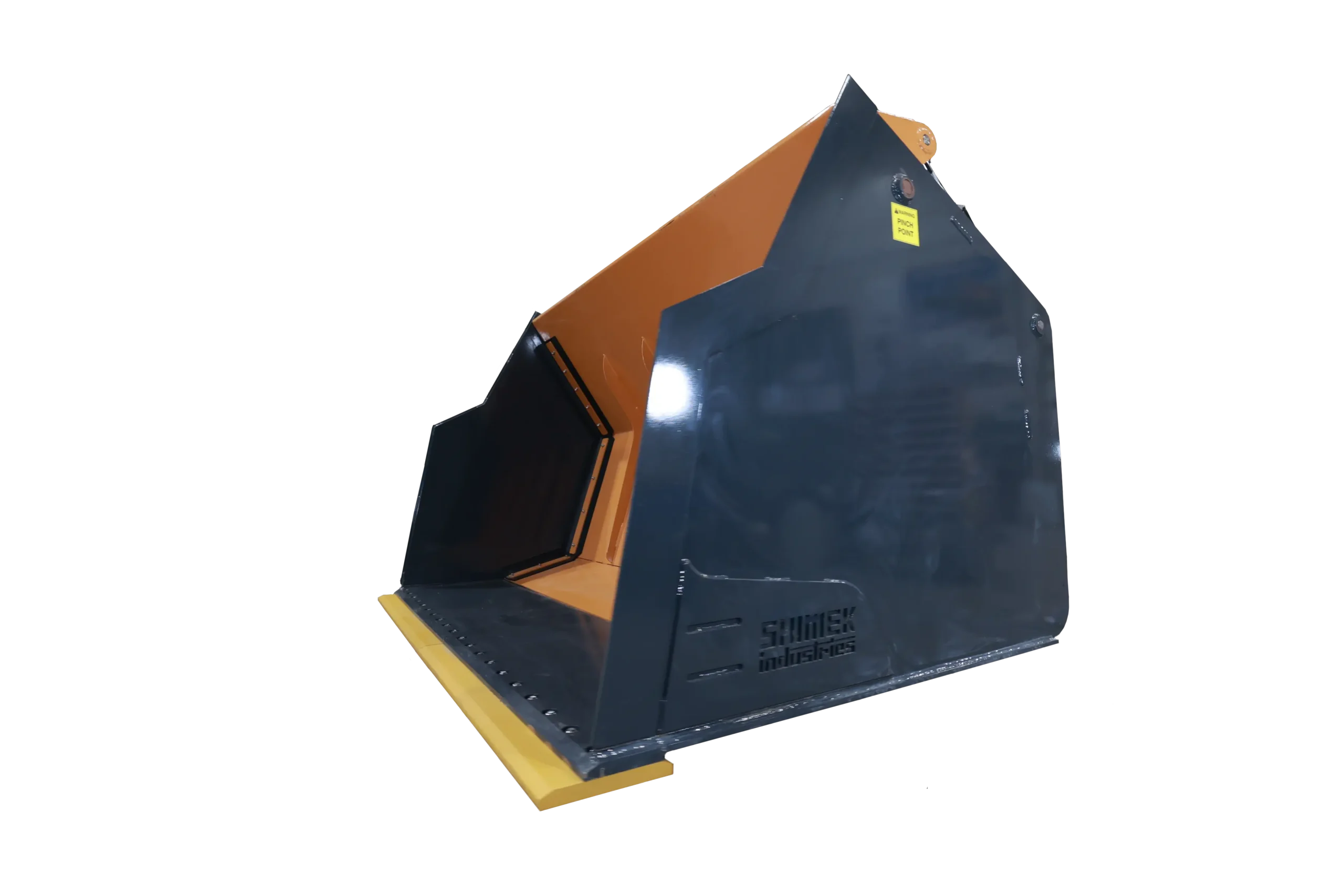

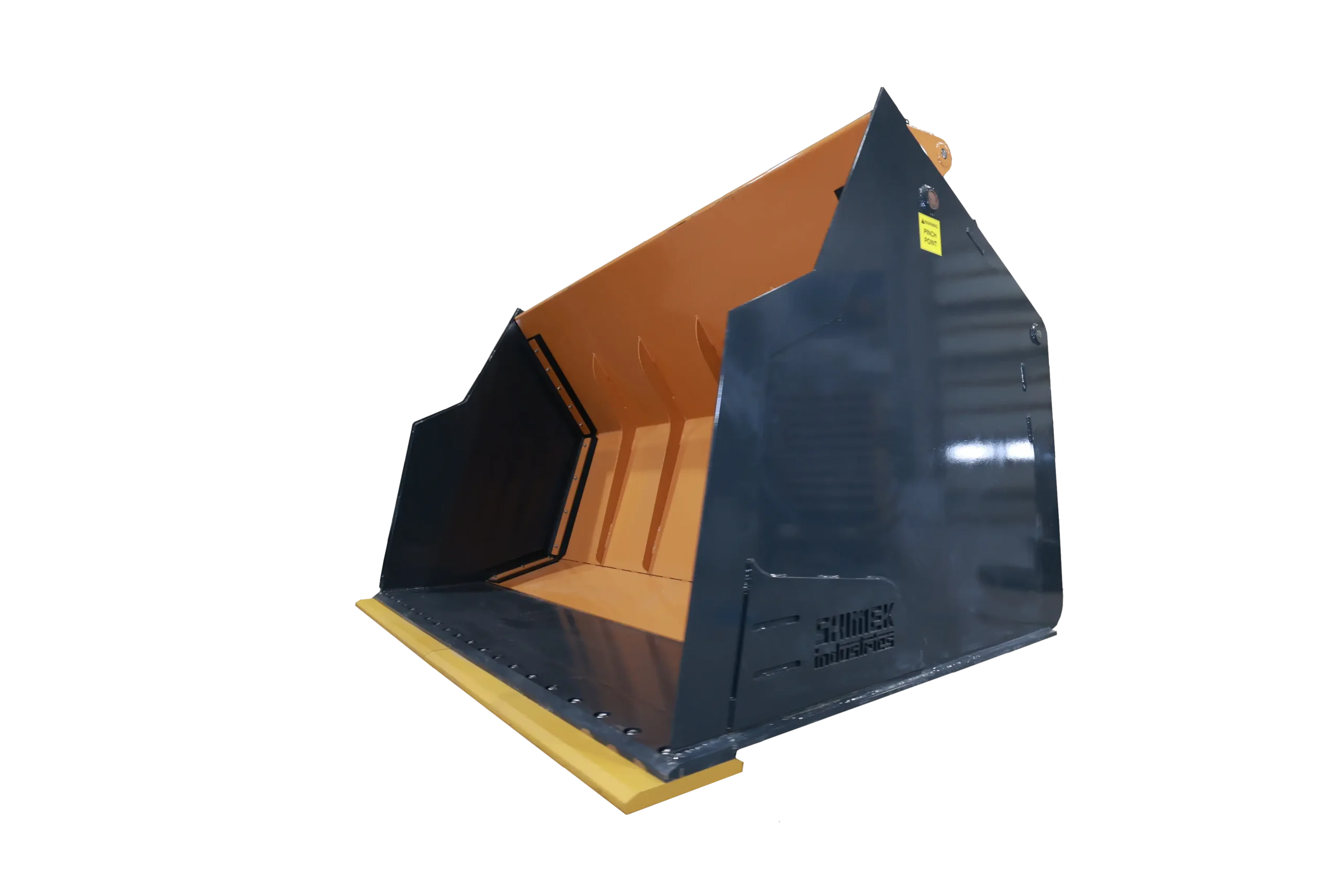

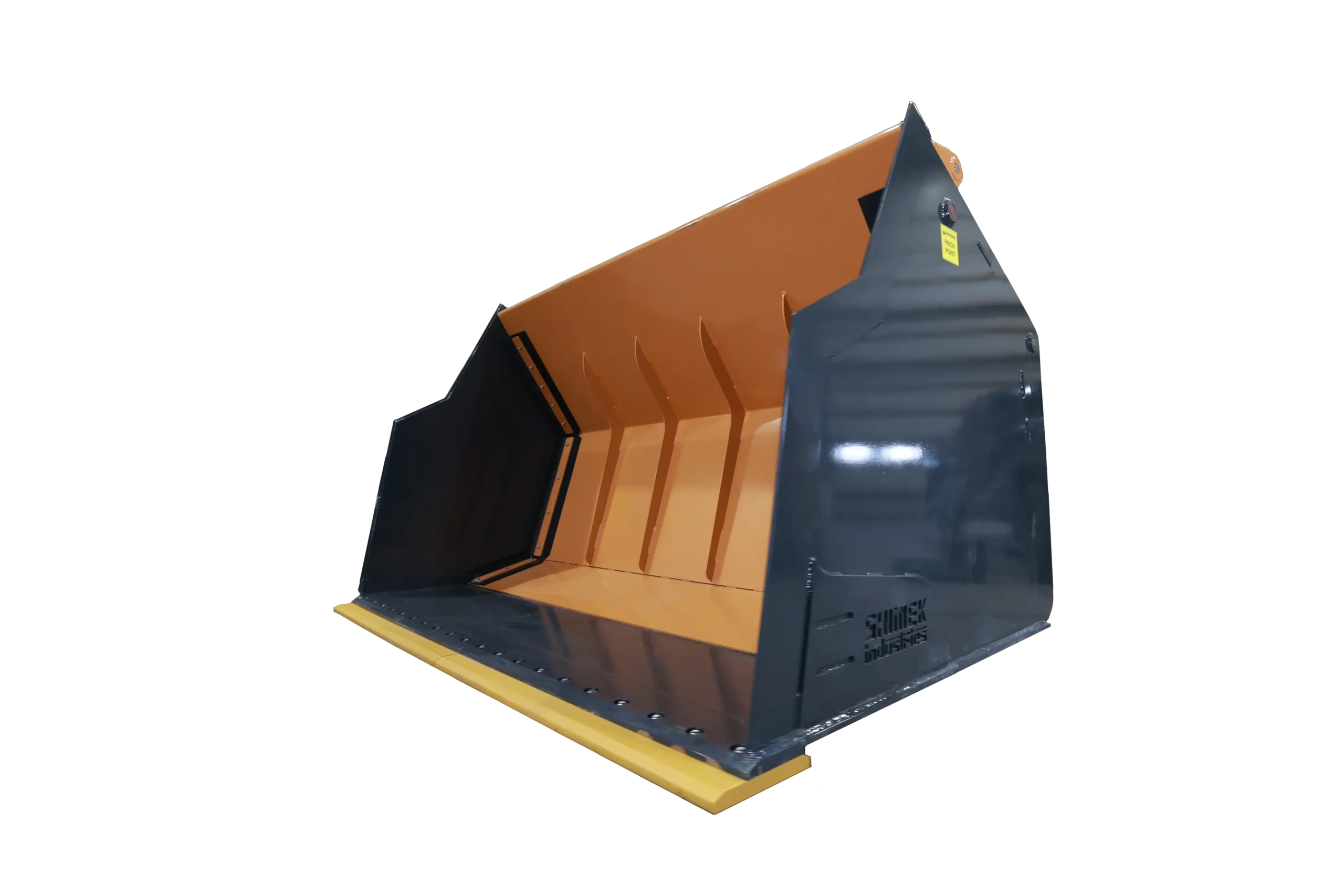

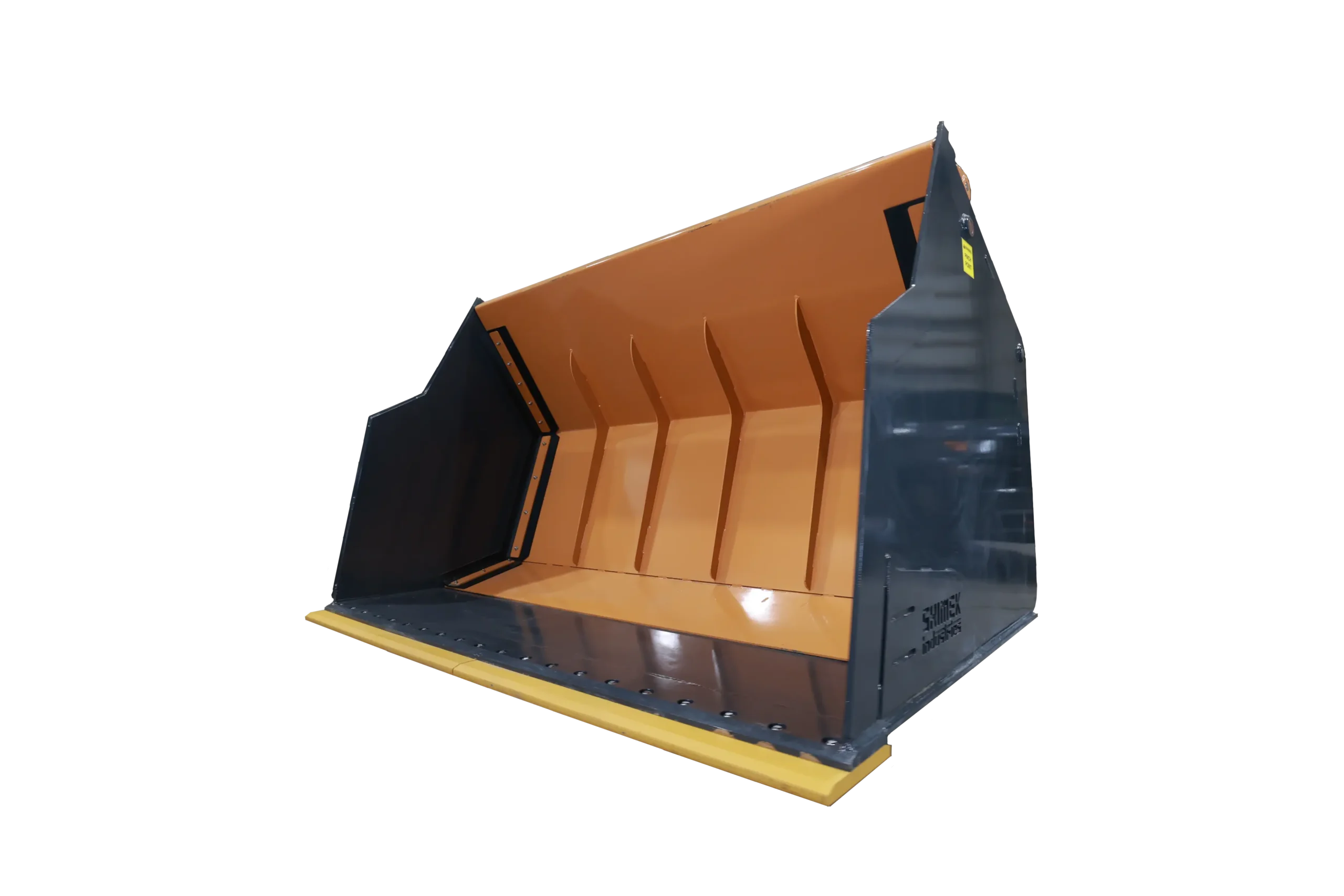

Every feedlot, every loader, every environment has a unique set of variables. At Shimek Industries we don’t believe one-size-fits-all is good enough. If you’re wrestling with inefficient attachments, mismatched loaders, or custom challenges nobody else has solved, it’s time to talk custom design.

Why custom attachments matter

- Standard buckets and attachments are built to average scenarios. When your feed pile, material type or loader setup deviates, those “averages” become inefficiencies.

- Custom designed attachments let you optimize fit, function, and durability — meaning less downtime, fewer repairs, and more productivity.

- At Shimek, we back that claim with our Custom Projects page: “If you can dream it, we can build it … From custom buckets and attachments to trophy trucks, stools and more, our fully-equipped design & fabrication shop brings ideas to life.” Shimek Industries+1

The Shimek Approach: Design → Build → Performance

- Consultation: We listen. What’s your machine, what are you handling (e.g., heavy wet feed, sticky manure, scraping pens), what are your pain points?

- Engineering & Fabrication: Using precision engineering, durable materials and a full fabrication shop, we tailor the attachment. Again, per their site: “precision engineering and expert craftsmanship” is standard. Shimek Industries+1

- Fit & Finish: The custom design ensures the attachment integrates seamlessly with your machine — loader connections, hydraulic circuits, centre of gravity, cycle time, etc.

- Long-term support: We don’t just deliver the bucket and walk away. We support durability, wear parts, maintenance planning.

Example use cases where custom beats stock

- A feedlot loader that struggles with wet, heavy silage blend: custom bucket optimized width/depth for improved fill and eject clearance.

- Pen-scraping excavator in a high-abrasion environment: custom tilt bucket with stronger sidewalls, wear-liners, proper tilt geometry.

- Specialty job: grabbing round bales, handling bulky brush, or retrofit onto older machines where dimensions don’t match standard buckets.

ROI you can count on

- Labour savings: less time per scoop, fewer passes, less operator fatigue.

- Reduced feed loss & better throughput: optimized bucket shape or ejector design means more of your feed goes into bunks, not wasted.

- Lower maintenance/repair cost: When attachments are designed with your conditions in mind (material, wear zones, machine interface), they last longer and need fewer fixes.

- Flexibility for the future: Your operation evolves; custom attachments give you the flexibility to adapt, rather than re-buy generic kit.

Final word

Don’t settle for the “good enough” bucket when you could have one designed for your operation. If your loader, your materials or your cycle demand something different, start the conversation with Shimek Industries. Let’s build performance into your attachments.