Your vertical TMR mixer is the heart of your feed blend system. It mixes, it distributes, it sets the tone for animal performance and feed efficiency. But like any workhorse, the tub, augers and discharge get hammered. Here’s how partnering your mixer with the right bucket—ideally a custom or well-matched bucket from Shimek Industries—can extend your mixer’s life and improve overall ROI.

The wear cycle in a vertical TMR mixer

Vertical mixers (those “tower-style” tubs with augers) are designed to process variable ingredients: hay, silage, grain, liquids, etc. According to feed-industry literature:

- Tub walls, floors, auger flighting, knives and knives carriers are subject to constant abrasion and mechanical impact. countrytractor.ca+1

- If feeders are overloaded, materials are too long or heavy, or loaders aren’t matched, the mixer works harder, heat builds, wear accelerates.

- The result: increased maintenance, downtime, and ultimately earlier replacement than planned.

Where the loader bucket enters the equation

Your loader bucket is the front end of the entire feeding system — what you feed into the mixer, how you feed it, how consistent your loads are. A mismatched or inefficient bucket can inadvertently accelerate wear in your mixer. Here’s how:

- Poor fill shape or oversize loads: If the bucket delivers large, imbalanced or oversized loads, the mixer must compensate, increasing stress on auger, floor and sides.

- Excess carry or spillage: Inefficient bucket geometry can lead to spillage, returns, uneven mix loads — again making your TMR unit work harder.

- Extra passes / longer cycle times: Poor bucket performance means more cycles per day. More cycles = more rotations = more wear.

- Inconsistent feed quality entering the mixer: Variation in load density, particle size or moisture means your mixer must do extra mixing, which increases internal abrasion/impact.

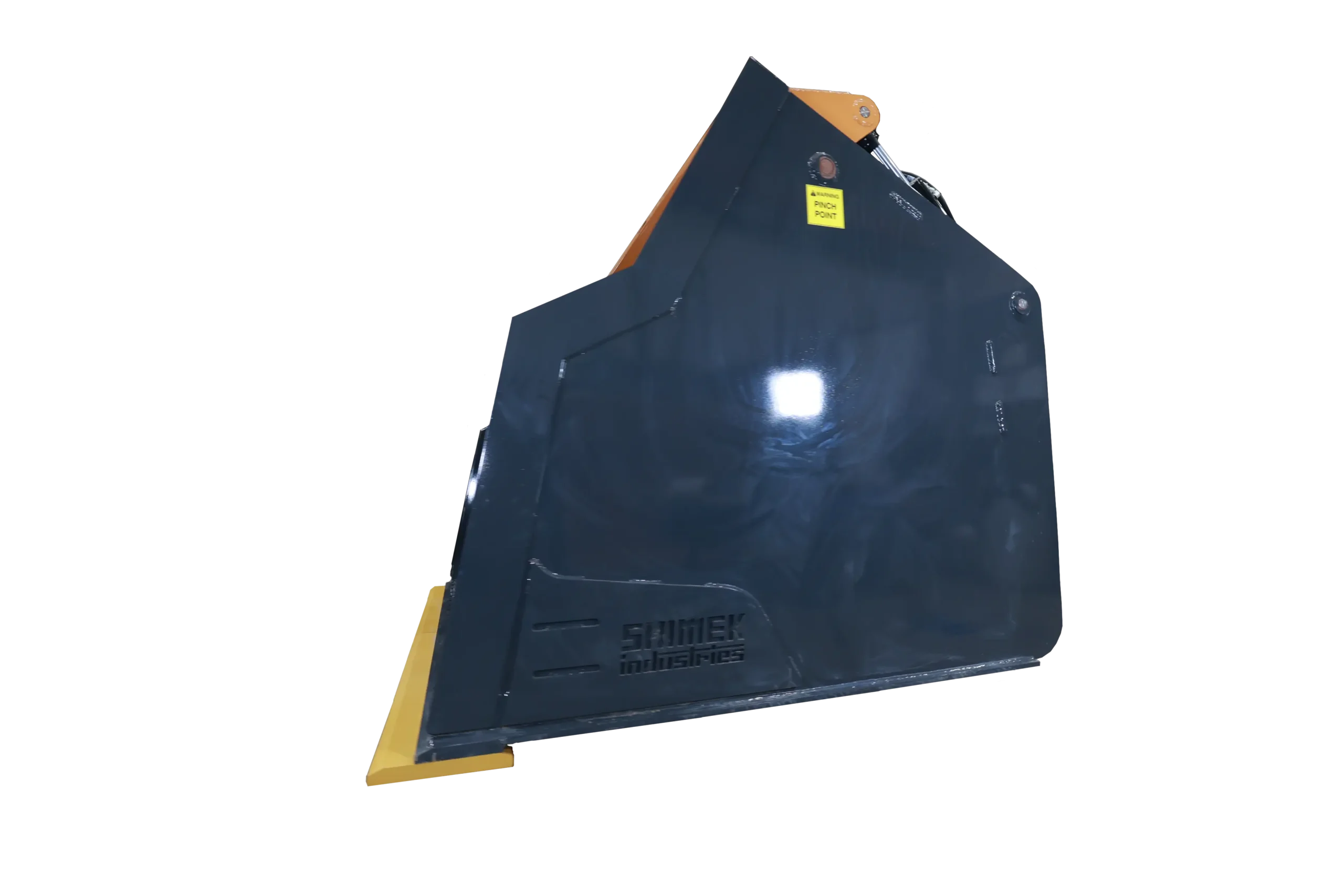

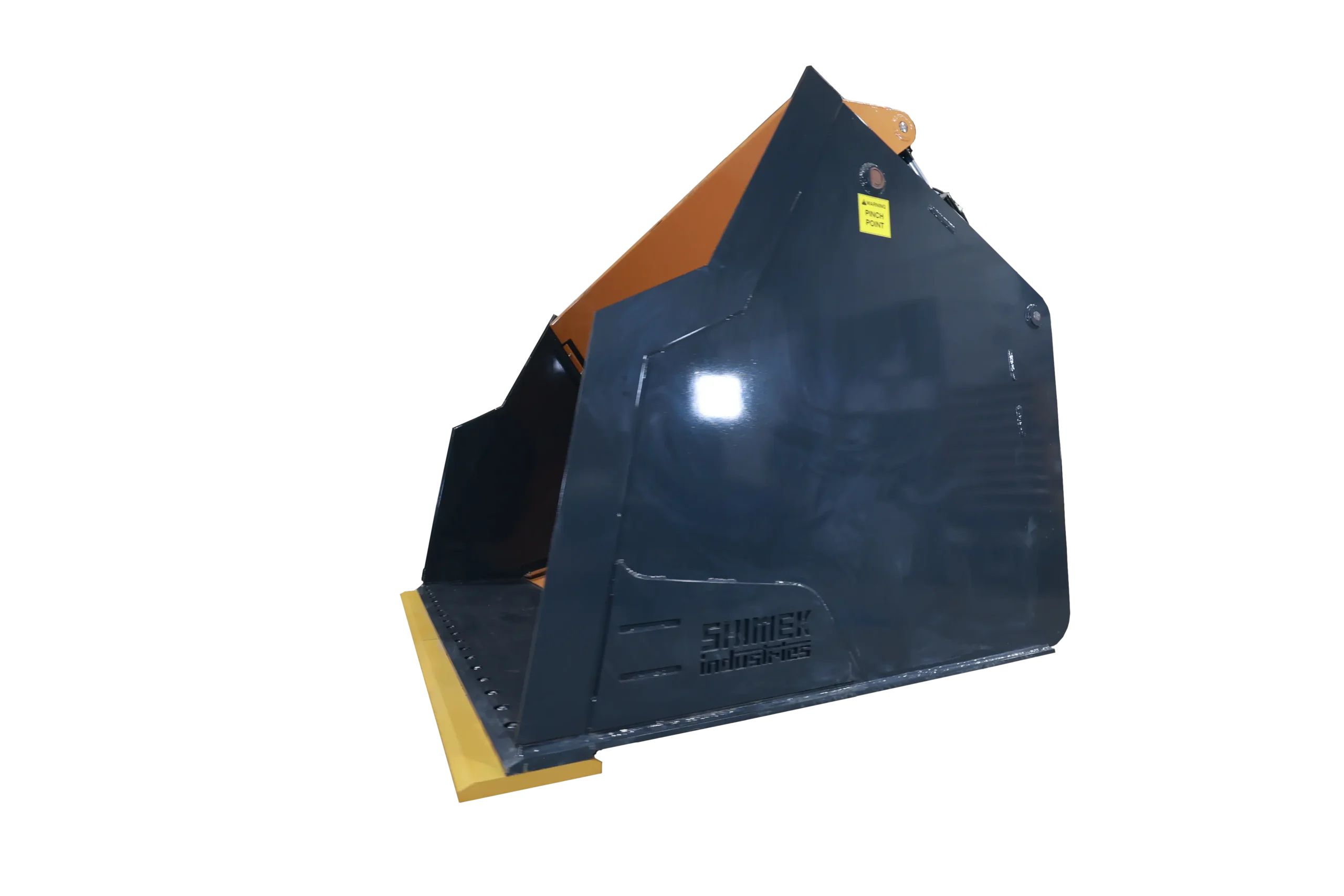

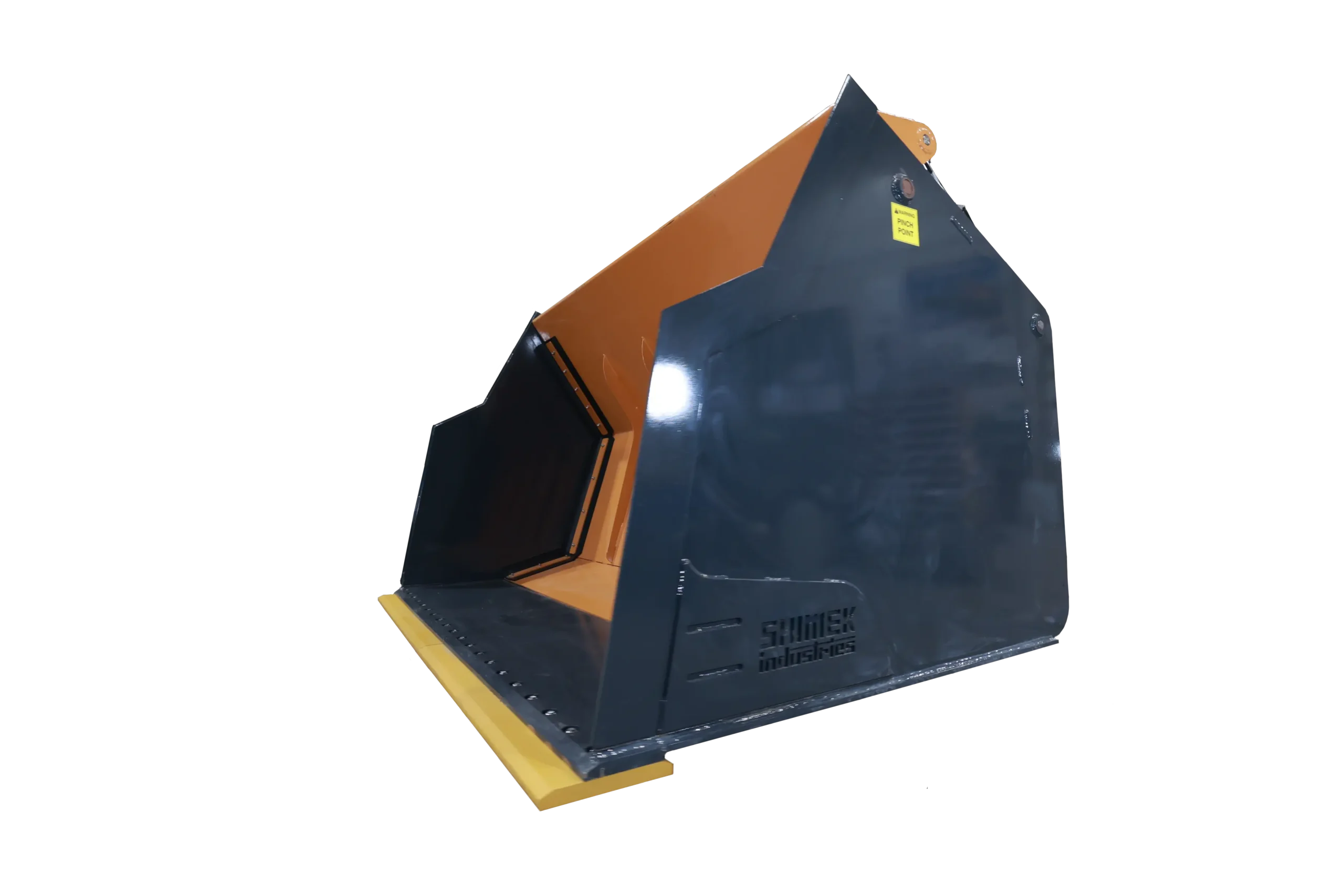

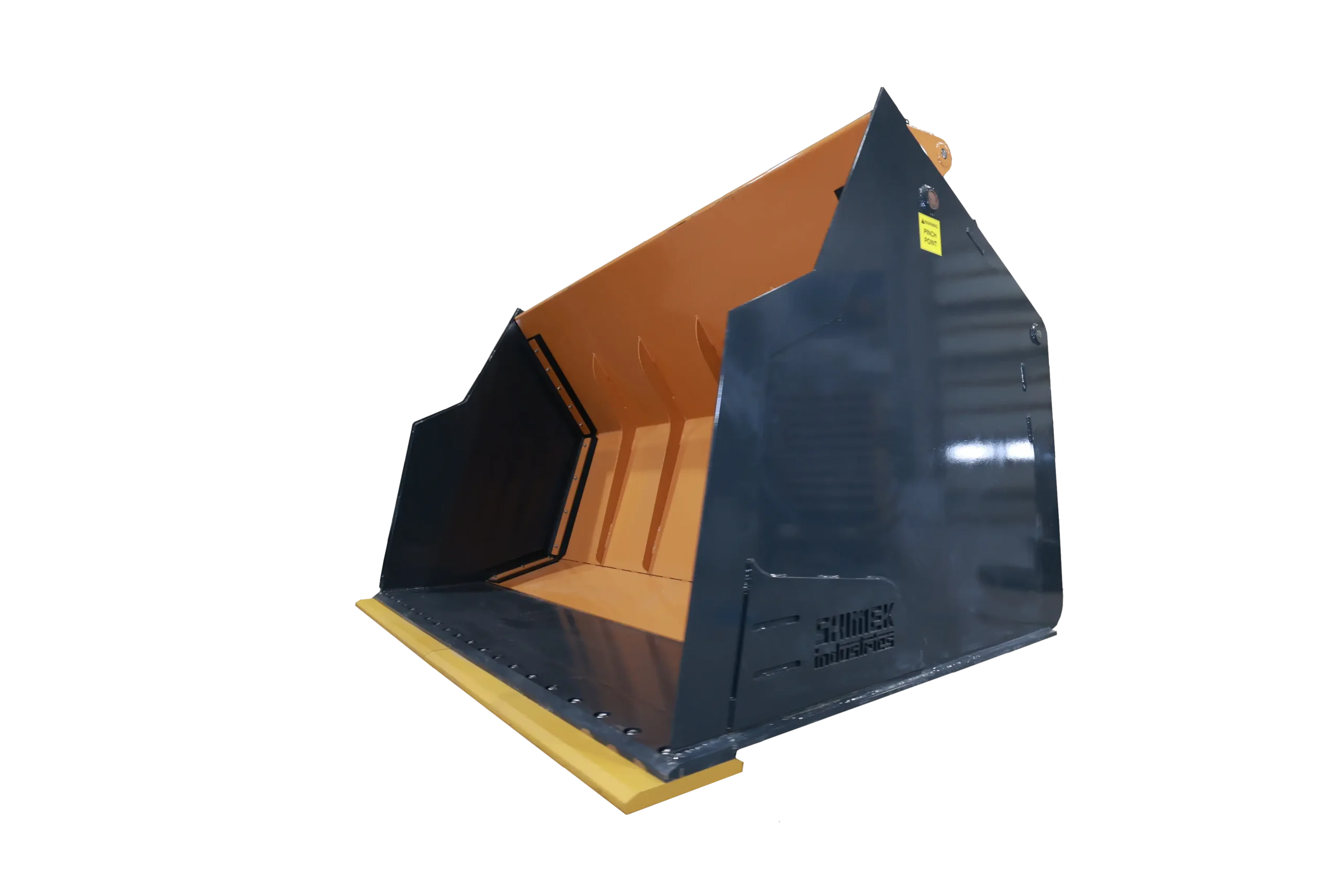

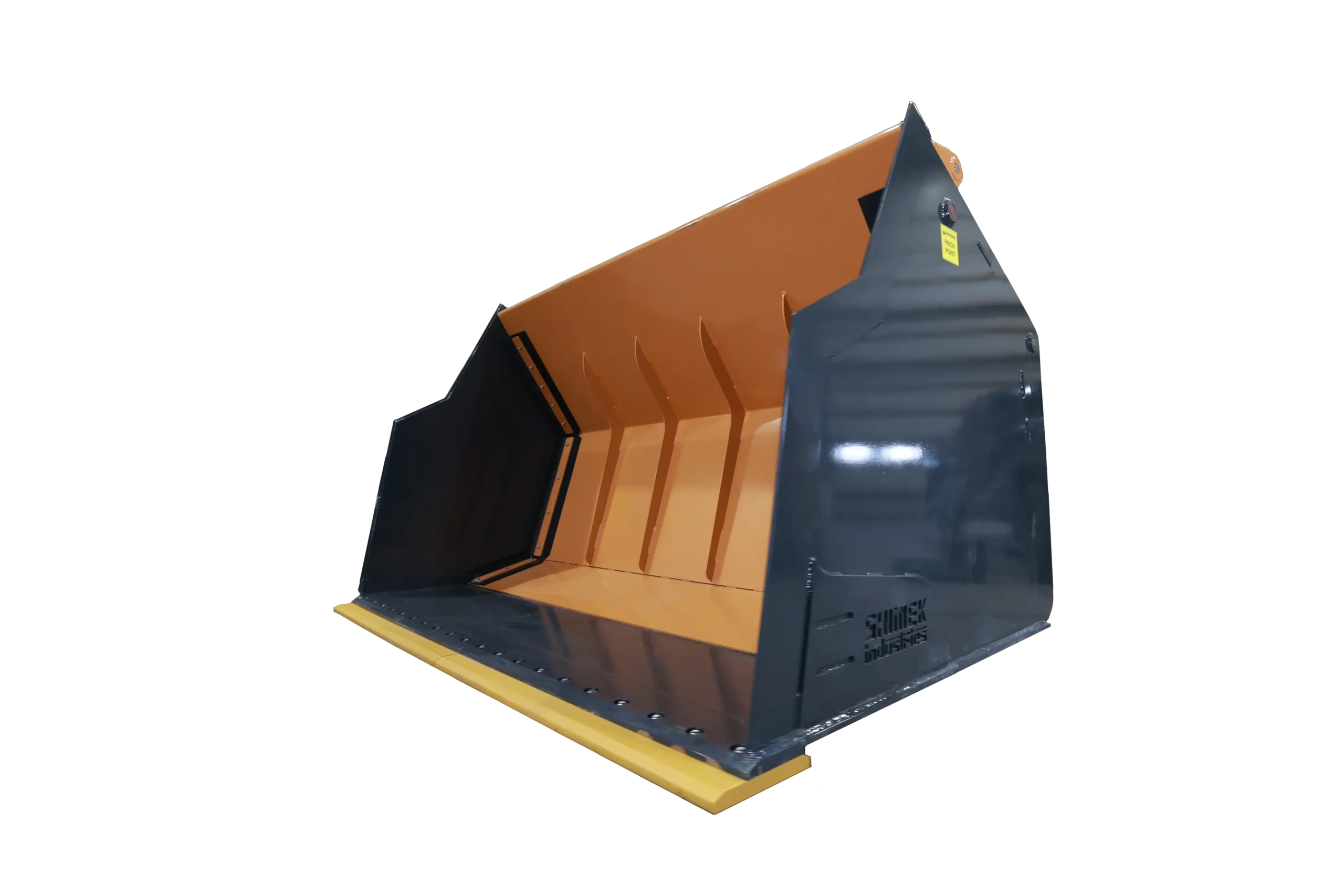

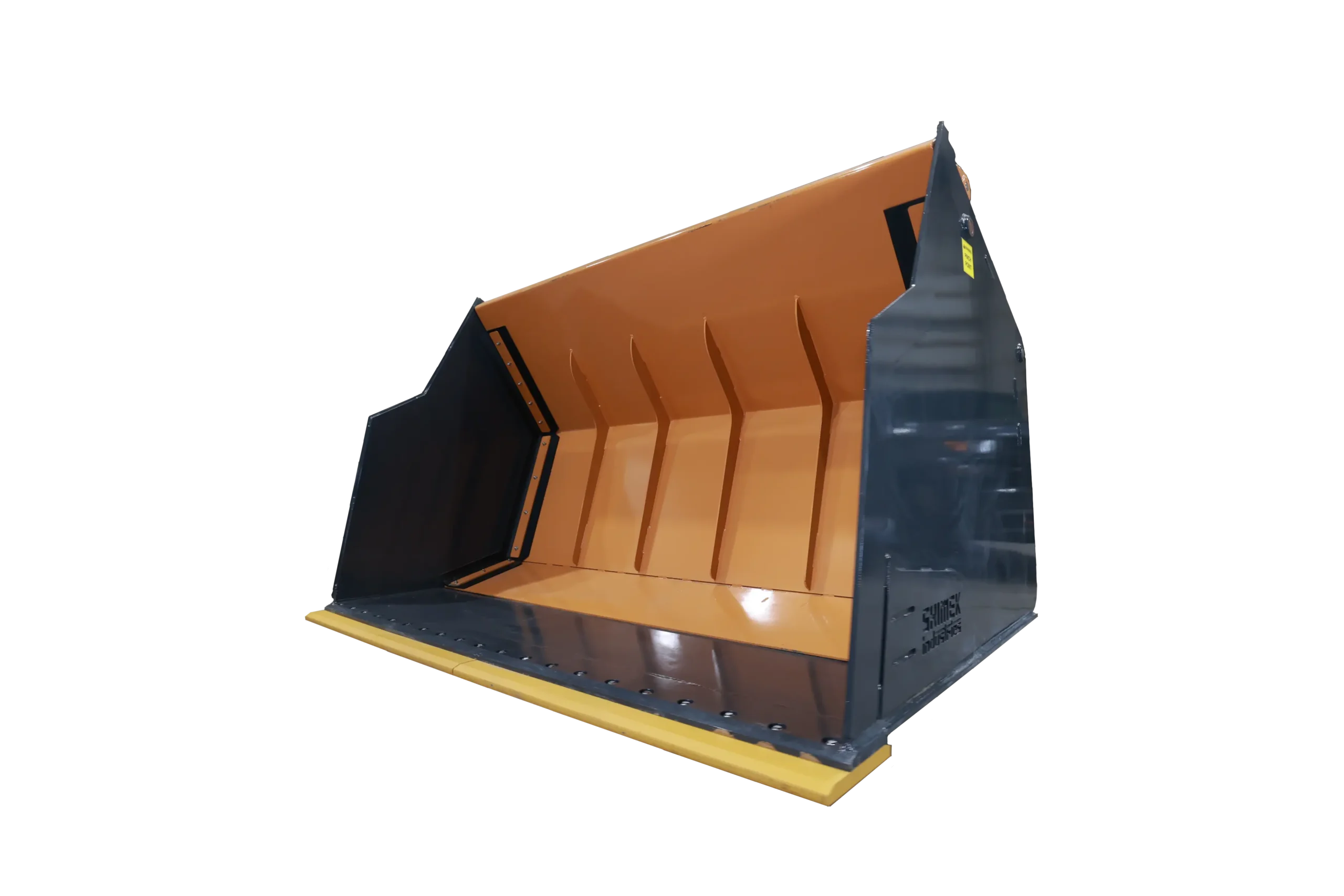

How a Shimek bucket can make a difference

- Optimised shape & door/eject geometry: Shimek’s buckets (including ejector-type) help deliver consistent, uniform loads that the mixer can handle more efficiently.

- Durable construction: Built for feedlot/mixer conditions — less deformation, fewer surprise load shifts, better material control.

- Match loader-mixer interface: By tailoring a bucket to your loader and your mixer’s load spec, you can hit the optimum volume and avoid overloading the tub or causing imbalances.

- Reduced return trips & spillage: A bucket that holds more of what you want (and less waste) means your mixer sees better-conditioned feed, fewer adjustments and less “overwork”.

The bottom line: extended mixer life + better economics

- Lower maintenance & downtime: When your mixer isn’t fighting bad loads, wear slows; components like floor plates & auger flighting last longer.

- Better feed consistency: A good bucket ensures what the mixer gets is what it expects — which means less time chasing inconsistencies and more time feeding.

- Reduced total system cost: The mixer may cost a lot, but the cost of a loader bucket is relatively small. Investing in the right bucket is a high-return move.

- Operator efficiency: Easier, faster loading means fewer passes, less fatigue, fewer variables thrown at the mixer by poor upstream performance.

Quick checklist before you spec a bucket for your TMR system

- Has the bucket been fitted to match your mixer’s optimum load size (volume, weight)?

- Does the bucket preserve feed density (not just volume)?

- Is geometry designed to reduce spillage and handle your specific material (wet silage vs. dry hay vs. mixed feed)?

- Is the bucket built with wear zones suitable for your feedlot environment?

- Will the loader-bucket-mixer chain be balanced (cycle times, amounts, machine wear) rather than one machine compensating for another?

Final word

Your vertical TMR mixer is only as good as what you feed into it — and how you feed it. A smart bucket isn’t just a loader accessory; it’s an efficiency lever with real impact on mixer lifespan, feed consistency and system cost. Talk to Shimek Industries about designing or selecting the bucket that makes your mixer work smarter, not harder.