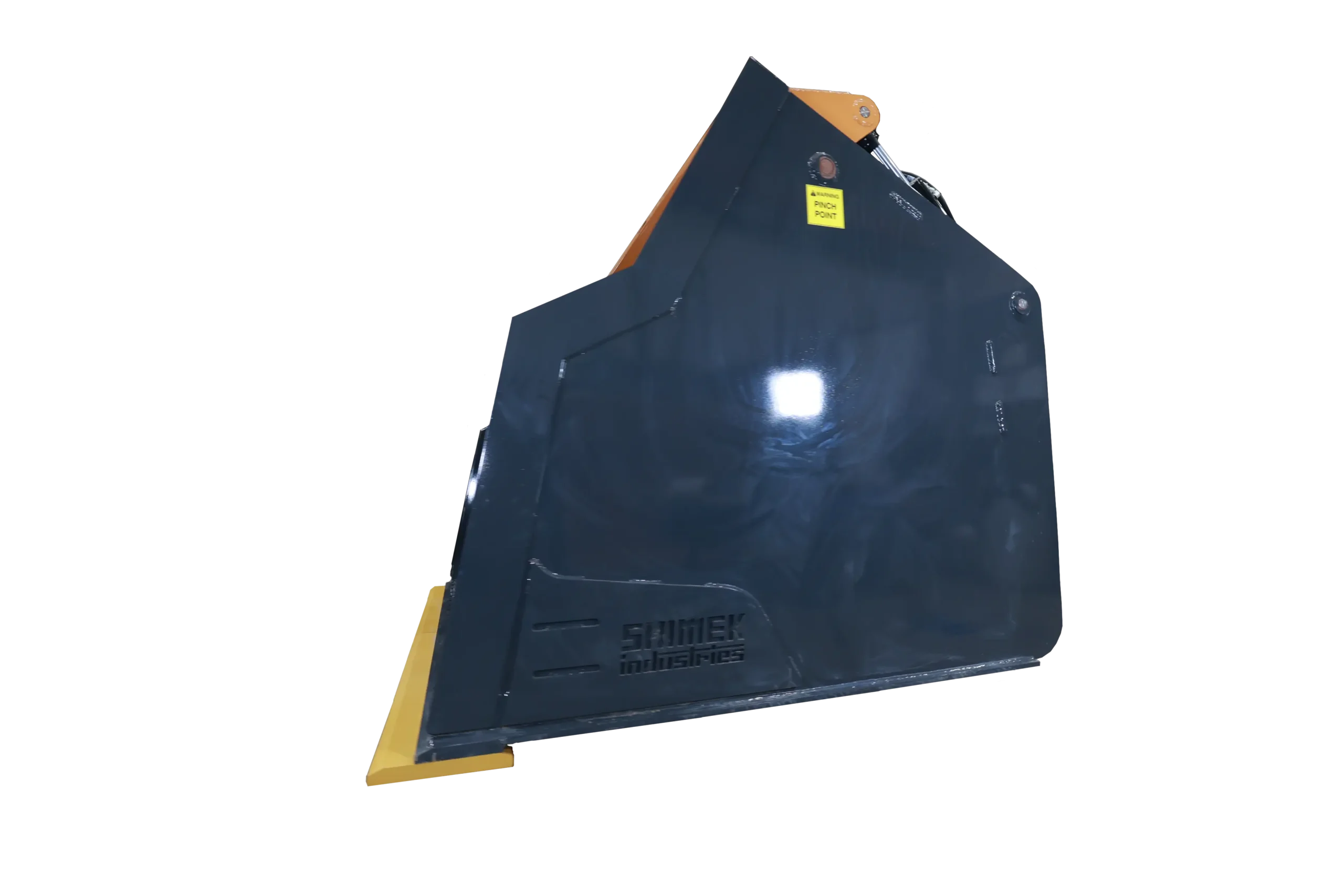

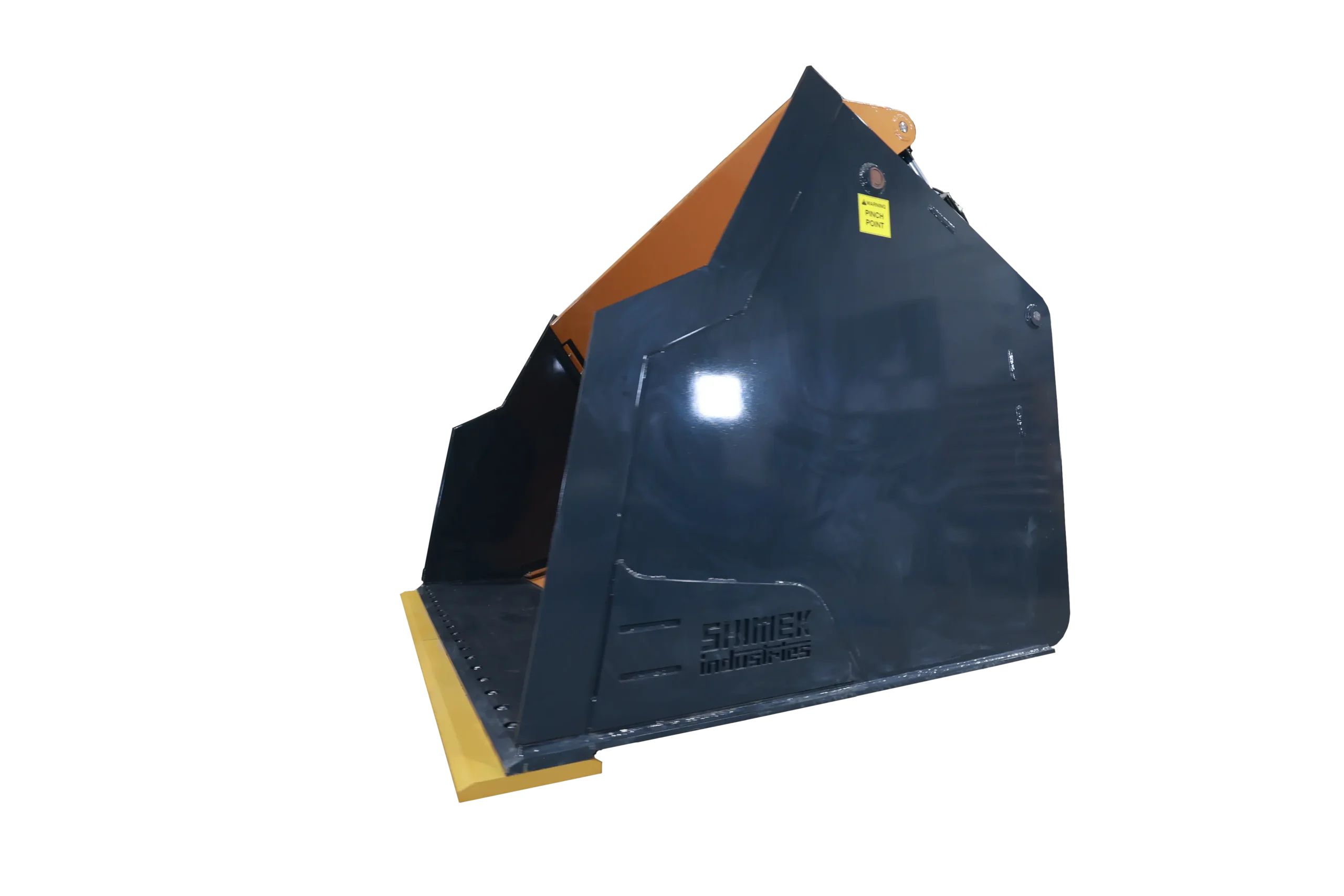

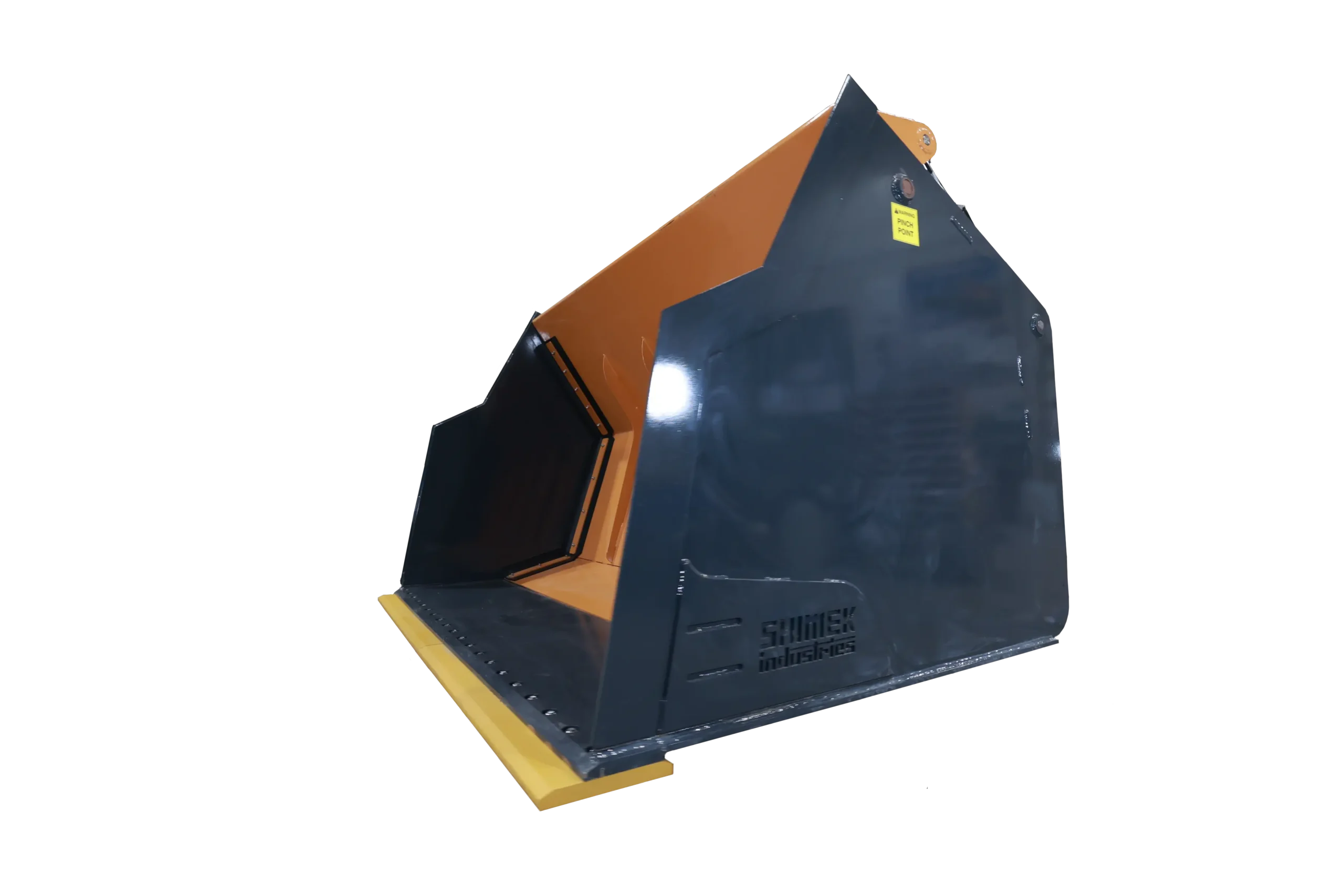

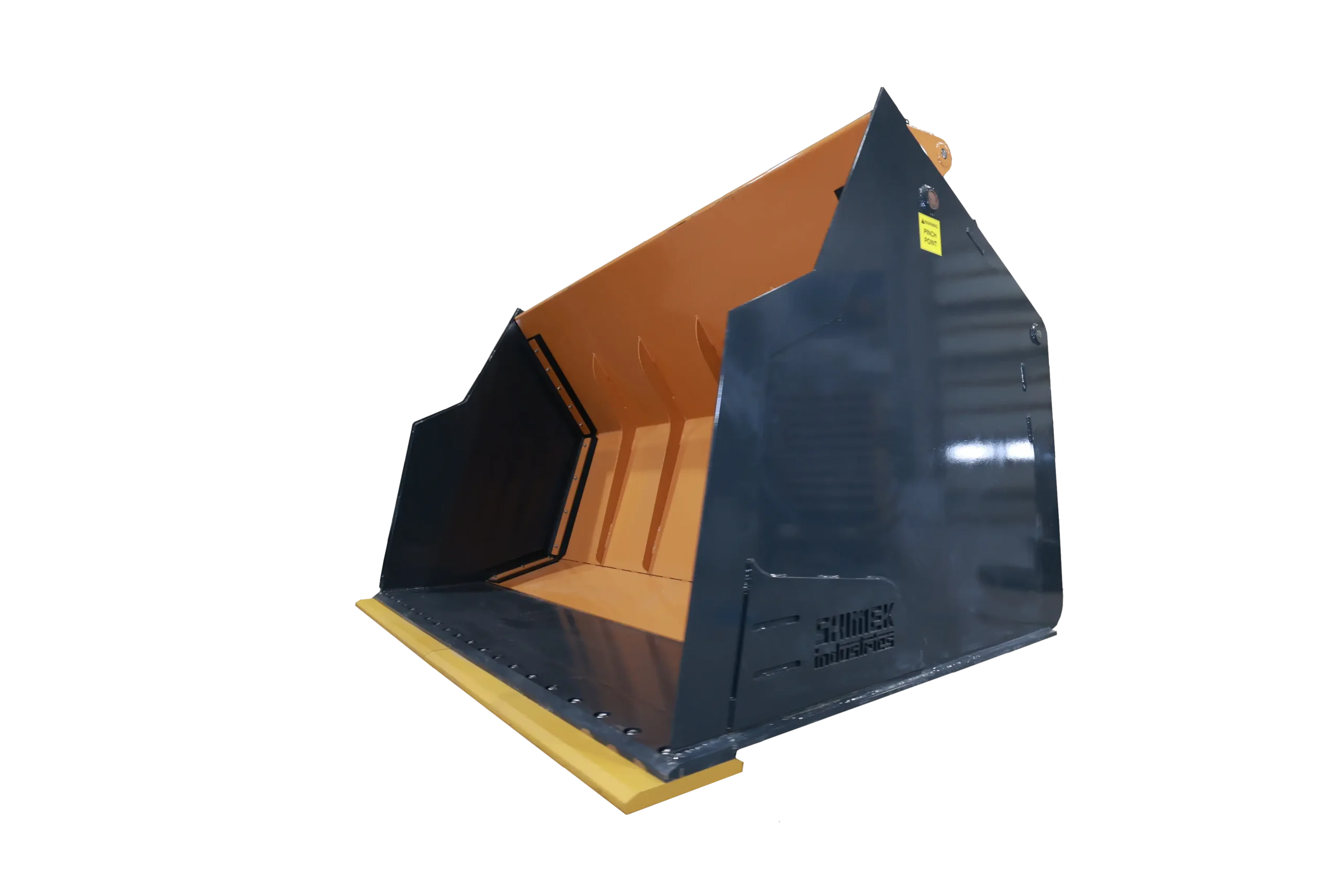

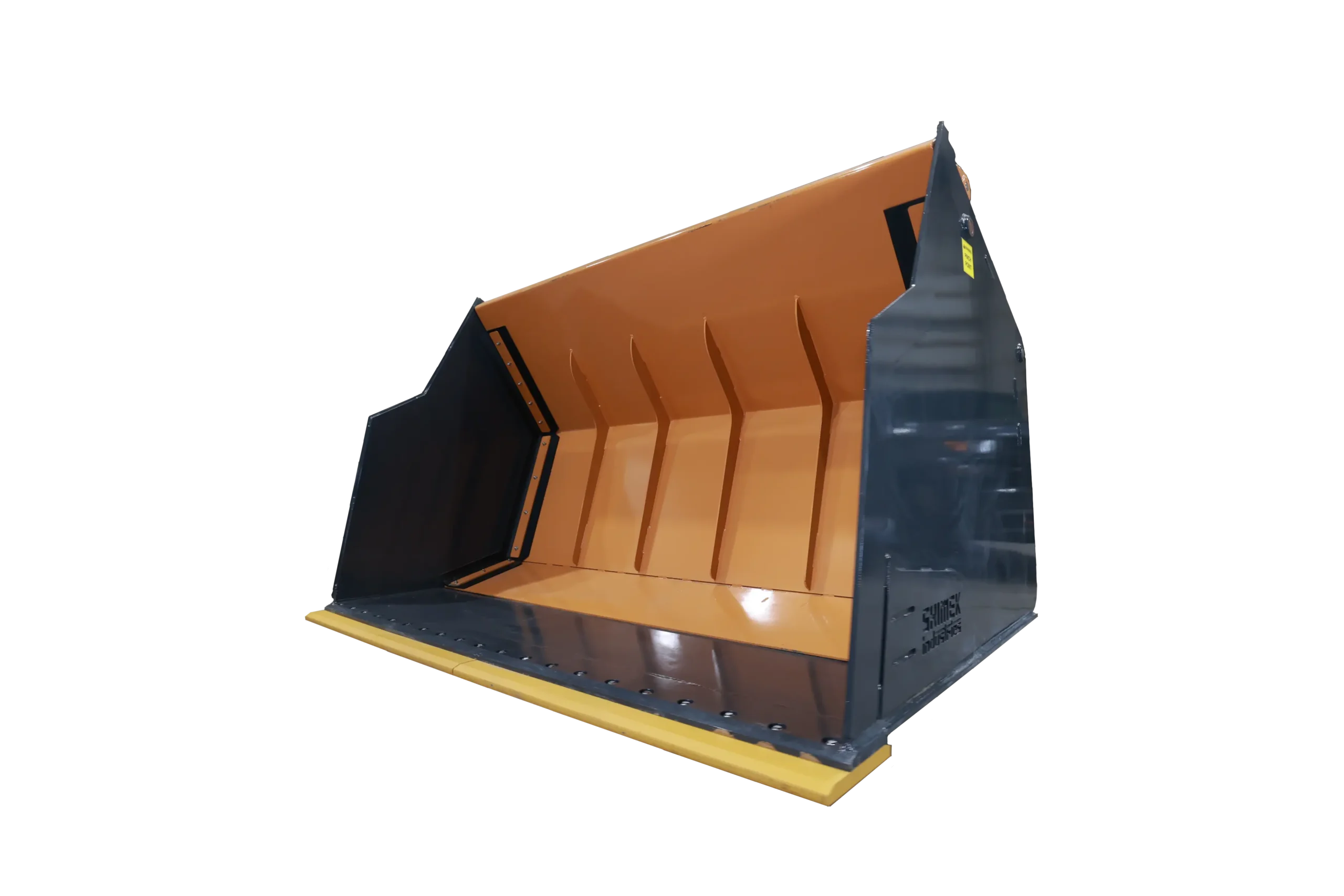

On a feedlot, feed and time are money. Shimek Bucket feedlot efficiency means moving material cleanly and quickly so you waste less and work faster—even through Lethbridge cold snaps and Southern Alberta’s freeze–thaw conditions.

Why Efficiency Counts In The Yard

- Less feed loss: Material slides cleanly instead of sticking or bridging.

- Reduced labour and fuel: Faster loads, quicker dumps, fewer clean-ups.

- Built for the grind: Heavy loads and harsh weather won’t slow it down.

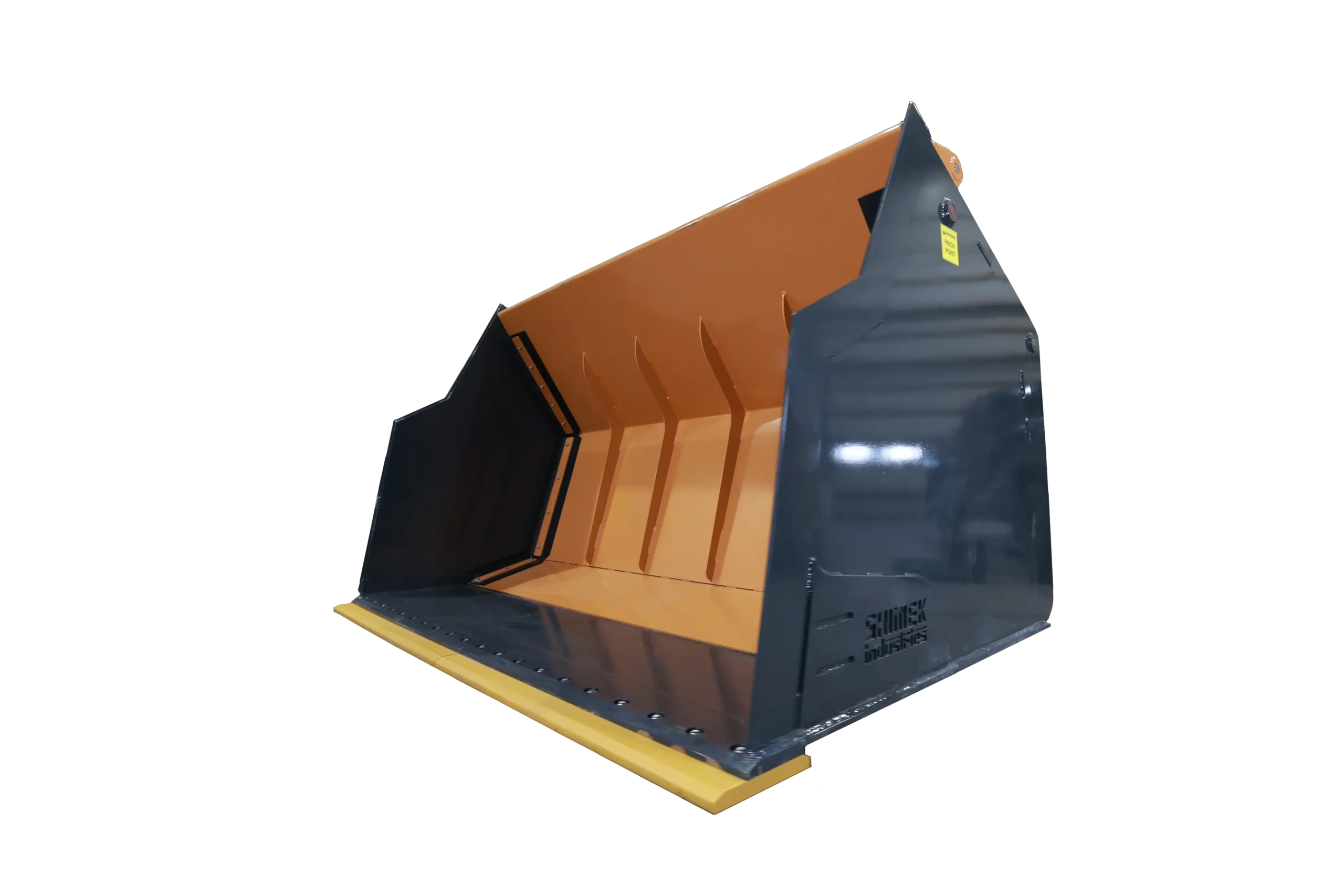

Features That Deliver Real Gains

- Optimized shape keeps silage and mixed rations flowing smoothly.

- Reinforced wear points extend service life where buckets typically fail.

- Loader-matched design ensures balance, visibility, and safe handling.

- Serviceable components simplify maintenance and reduce total cost.

Why Shimek Bucket Feedlot Efficiency Matters

Across feedlots in Lethbridge and throughout Southern Alberta, operators report quicker morning rounds, cleaner dumps, and fewer breakdowns—especially on frosty mornings when conventional designs struggle. Because the Shimek Bucket pushes out material rather than relying on gravity, wet feed releases predictably, shortening rounds and reducing fuel use. Over the season, those minutes add up to meaningful labour savings and less downtime.

The Payoff For Your Feedlot

- More feed delivered exactly where it belongs, with cleaner dumps.

- Less downtime from plugged or worn-out gear.

- Better cost control across the operation.

Learn More

Improving feed efficiency is a major driver of profitability. See the Beef Cattle Research Council’s overview for additional insights.

Next Steps: