If you run a feedlot, you know the equation: Margins are thin, inputs are high, and the cattle don’t wait. Choosing the right Shimek Ejector Bucket for feedlots is critical to staying profitable.

Introduction

For decades, the answer to moving massive amounts of silage, grains, and manure was simple but expensive: Buy Big Yellow. Caterpillar, John Deere, and Komatsu have dominated the feedlot landscape because they offered the reliability and, crucially, the lift height needed to clear tall vertical mixers.

But the machinery market is shifting. Brands like Hyundai, Sany, and LiuGong are arriving with machines that offer incredible breakout force and reliability for a fraction of the capital expenditure. Yet, some operators hesitate.

- “Will it reach the mixer?”

- “Will it hold up to 12 hours a day of banging sticky silage out of the bucket?”

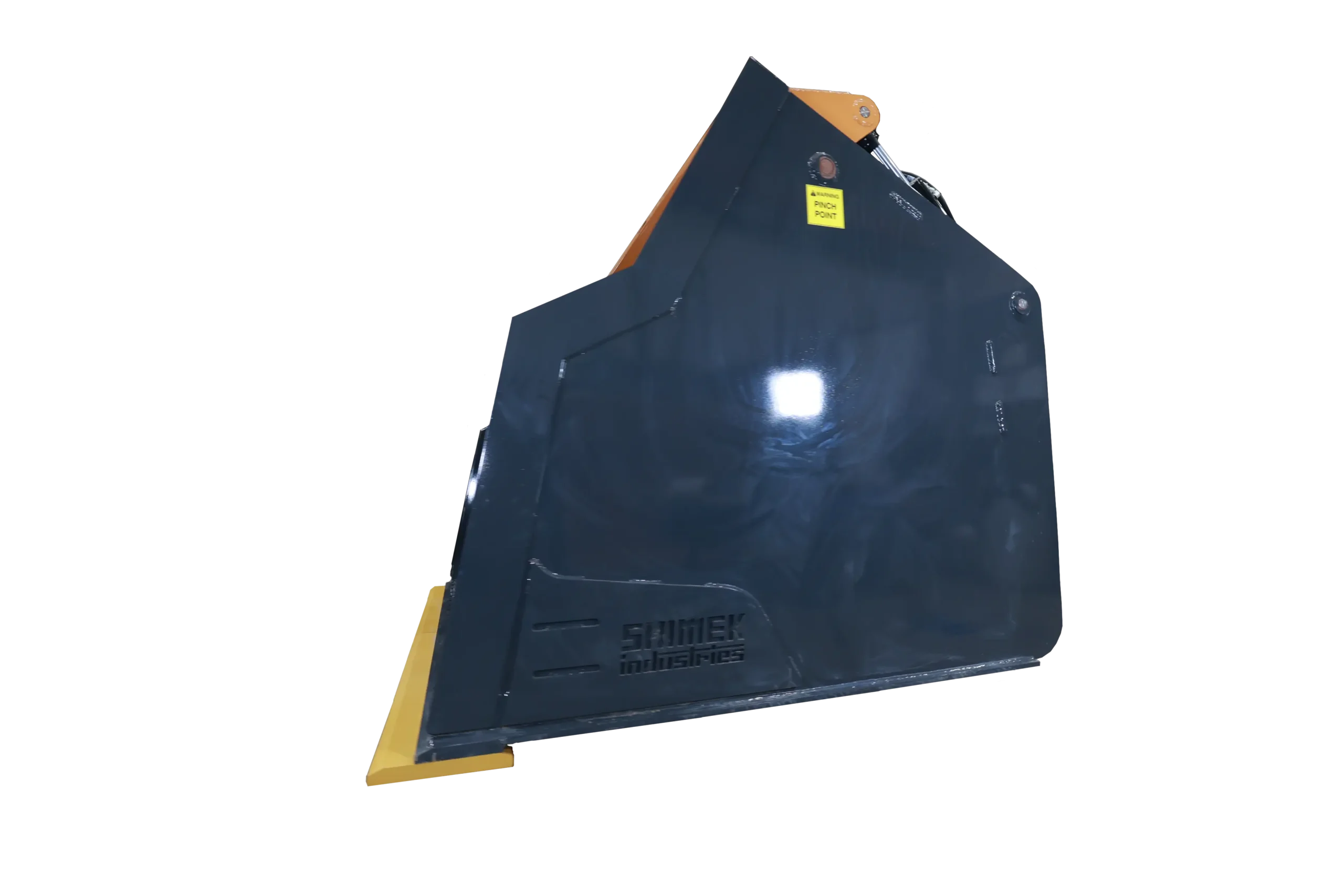

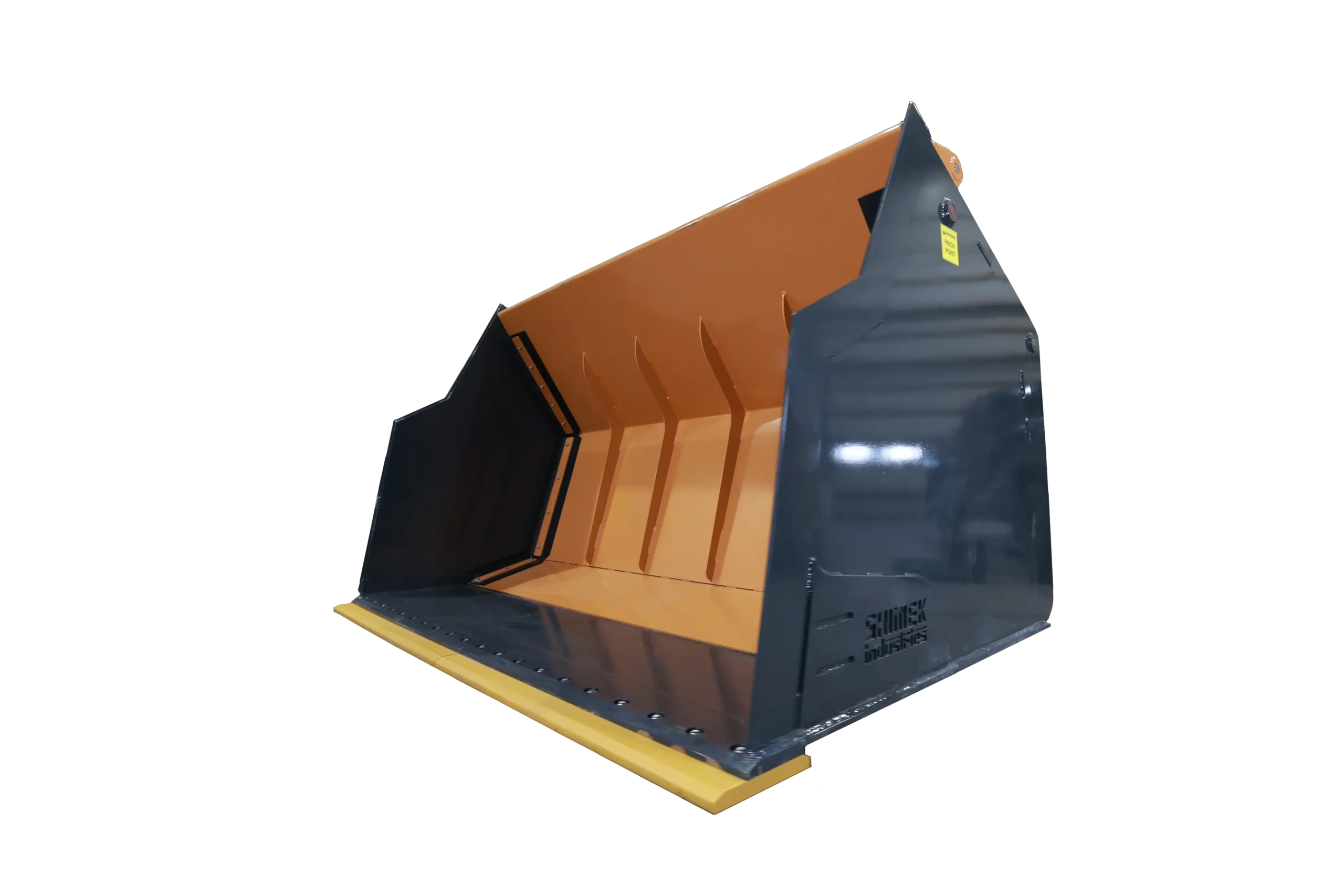

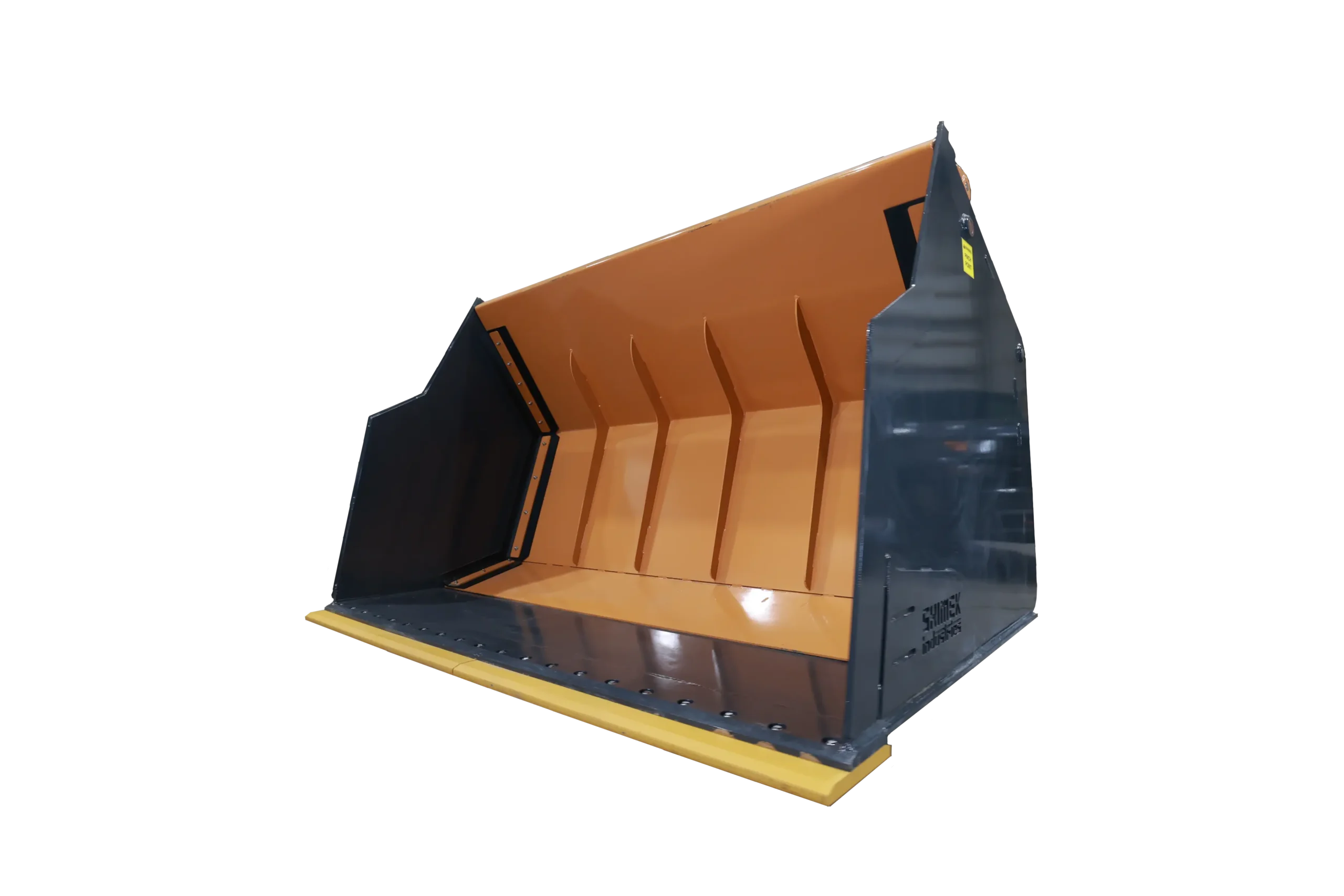

This is where the Shimek Industries Ejector Bucket changes the math completely.

By pairing a value-focused loader with a premium Shimek ejector, you aren’t just saving money on the purchase price—you are building a feeding machine that can often out-perform the big names in efficiency, precision, and maintenance.

Here is how the Shimek Ejector Bucket bridges the gap for Hyundai, Sany, and LiuGong owners.

1. The Shimek Ejector Bucket for Feedlots: Solving the Reach Problem

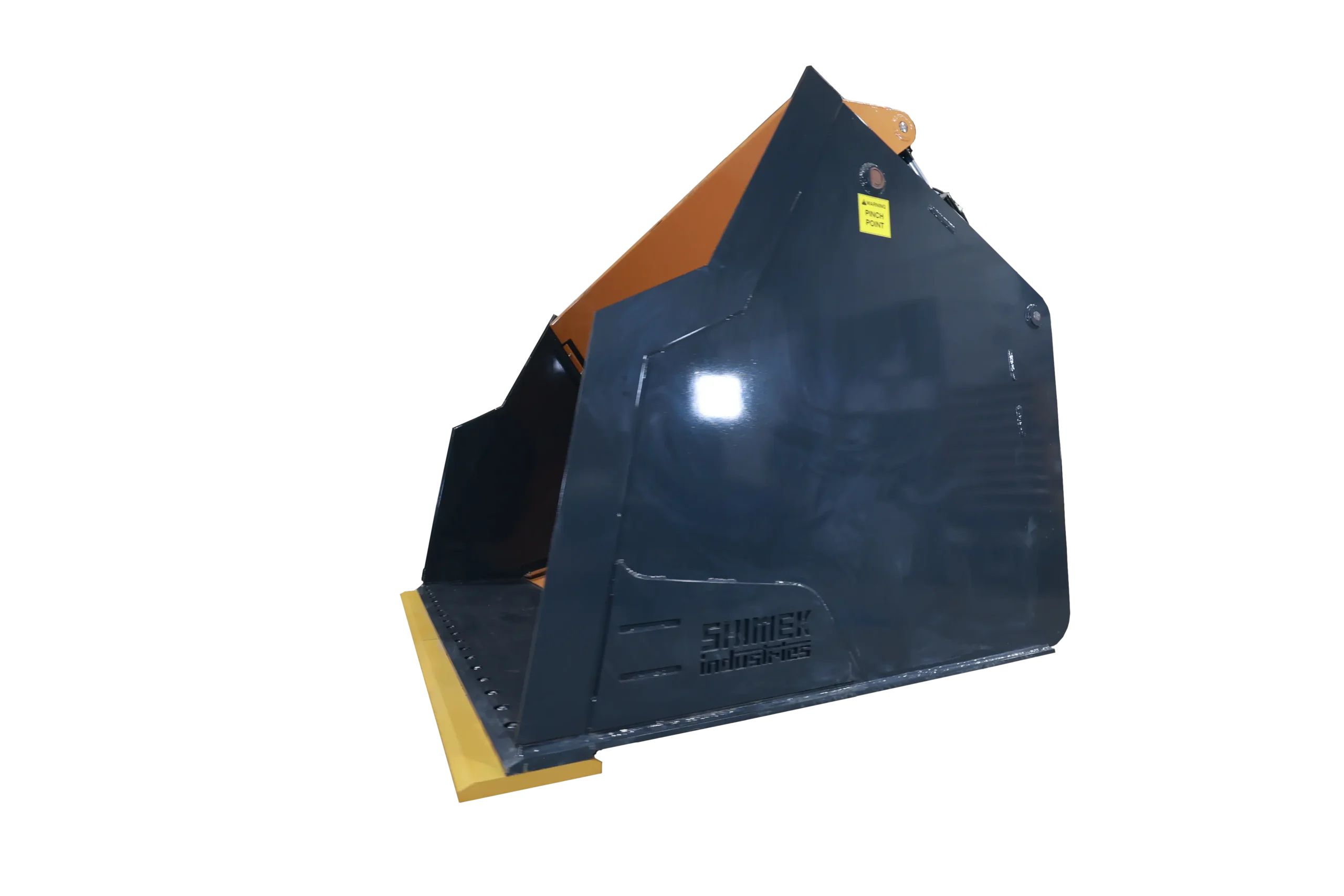

The single biggest objection to downsizing to a more affordable loader is dump height. Standard Z-bar linkages on smaller loaders often struggle to clear the top of a modern, high-capacity mixer wagon without spilling.

Usually, the fix is buying a larger, more expensive machine or opting for a “High-Lift” boom configuration (which reduces your tipping load and stability).

The Shimek Ejector Bucket solves this mechanically. Because the hydraulic faceplate pushes the material out rather than requiring the bucket to tip down and under, you effectively gain 24 to 36 inches of dump height clearance.

The Result: You can buy a standard-linkage Hyundai or LiuGong—saving thousands upfront—and still load the tallest mixers in your fleet without banging the side rails.

2. Precision Rationing: Stop Guessing, Start Metering

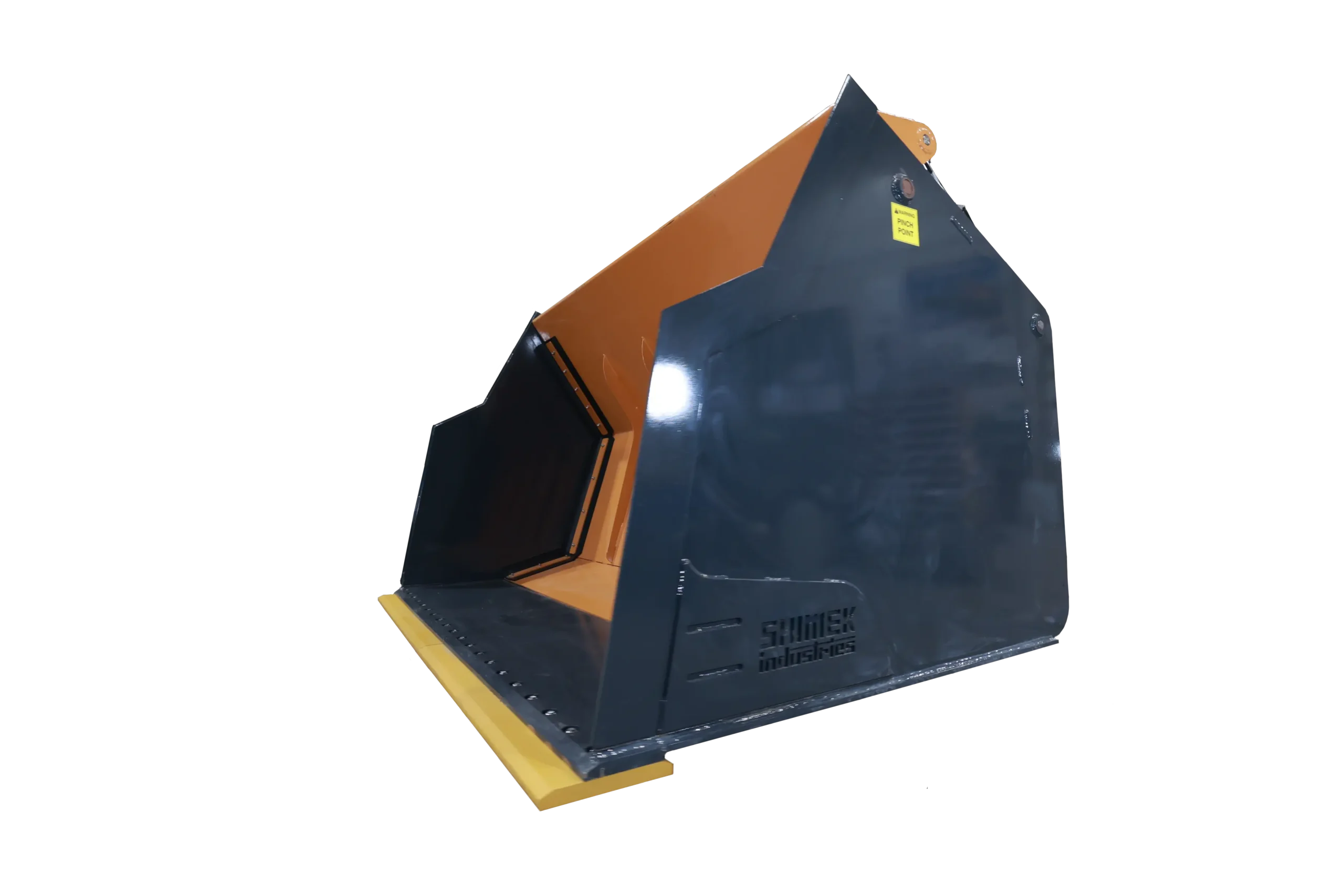

Feed is your biggest expense. When you are loading micro-ingredients or expensive supplements, the “dump and pray” method of a standard bucket is costing you money.

Standard buckets rely on gravity. When wet, sticky rations hang up in the bucket, the operator has to shake the loader arms to dislodge it. Suddenly, a 50 lb top-off turns into a 200 lb overage.

The Shimek Ejector gives the operator hydraulic control over the discharge. You can feather the hydraulics to push out exactly the amount of feed you need, stopping the flow instantly.

The Result: Your ration consistency improves, and your feed waste drops. A Sany loader with a Shimek bucket becomes a precision instrument, not just a blunt force scoop.

3. Saving the Machine (and the Operator)

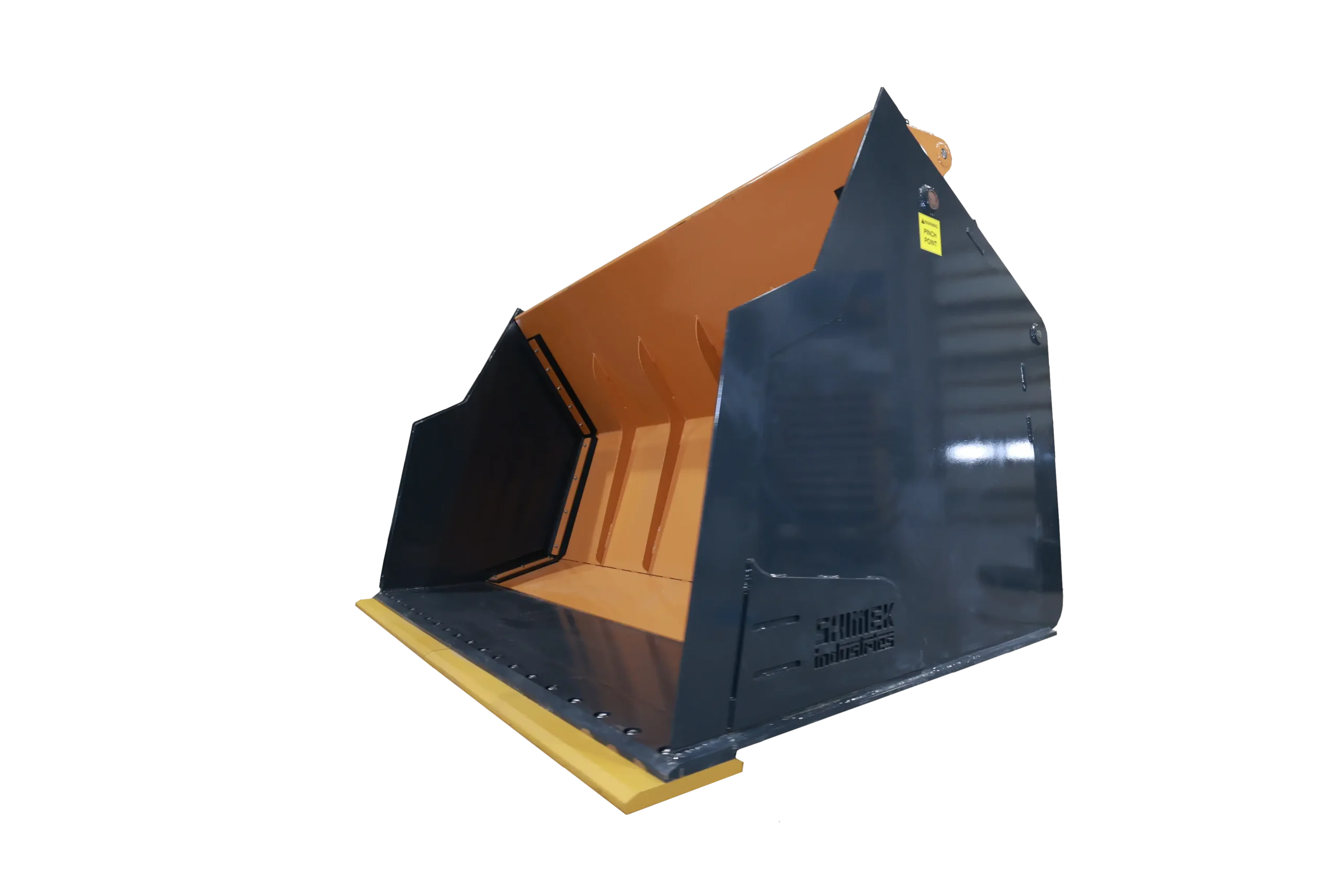

Watch a loader operator trying to empty sticky WDG or frozen manure out of a standard bucket. They slam the bucket stops, rev the engine, and shake the entire machine violently.

This “bang-to-empty” cycle is a killer for:

- Loader Pins and Bushings: Accelerated wear on the boom.

- Transmissions: Constant direction changes and shock loads.

- The Operator: Physical fatigue leads to mistakes.

The Shimek bucket pushes the load out cleanly with a neoprene-sealed faceplate. No shaking required.

The Result: You extend the life of your “value” loader significantly. A LiuGong or Hyundai creates less vibration and experiences less structural stress, ensuring that your lower-cost machine lasts just as long as a premium one.

4. Cycle Times: Speed Wins

In a feedlot, seconds count. The time wasted backing up, shaking the bucket, re-shaking, and waiting for material to fall adds up over hundreds of loads a day.

With an ejector bucket, the cycle is smooth: Approach, Lift, Push, Retract. Because the bucket doesn’t need to be fully dumped, you can often begin reversing while the faceplate is retracting. This fluidity shaves seconds off every cycle. Over a month of feeding, that is hours of engine runtime and fuel saved.

The Verdict: It’s Not About the Horse, It’s About the Tool

There is no denying that Cat and Deere make excellent machines. But in the modern cattle economy, ROI is king.

If you can purchase a Hyundai, Sany, or LiuGong for 20-30% less than the competition, and equip it with a Shimek Ejector Bucket for feedlots that gives you better reach, better rationing, and less wear than a standard bucket on a premium machine, the business case is undeniable.

You don’t need the most expensive logo on the grill to be the most efficient operation in the county. You just need the right bucket on the front.

Want to calculate your ROI? Contact Shimek Industries today to see how our buckets can transform your feedlot fleet.